Powerful 180mm Hole Saw for Woodworking and Construction Projects

By:Admin

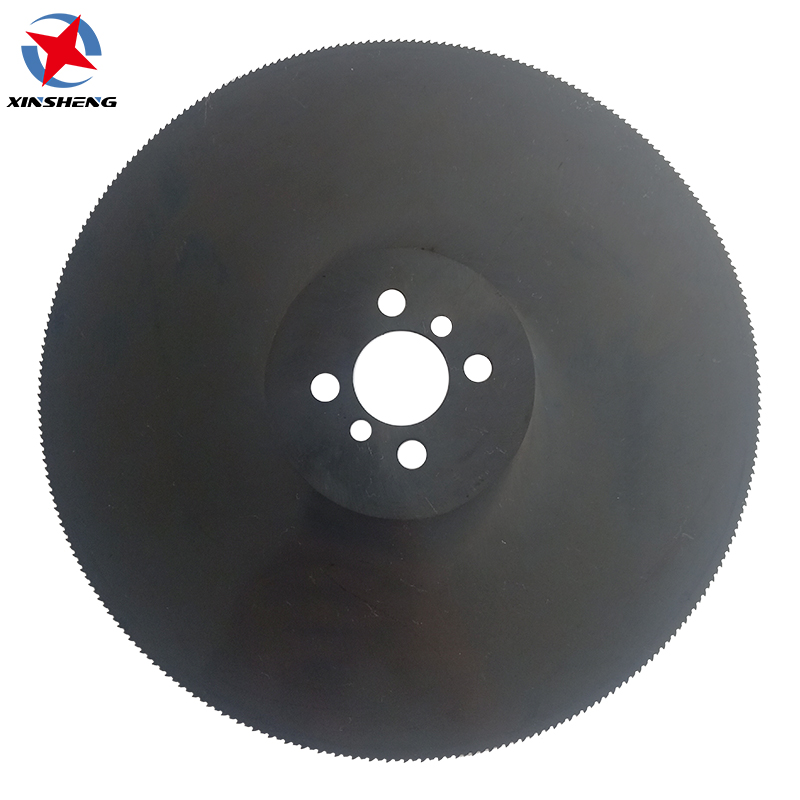

The construction industry is constantly evolving, with new tools and technologies emerging to make the building process more efficient and effective. One such innovation is the 180mm Hole Saw, a cutting tool that is set to revolutionize the way holes are made in construction projects.

The 180mm Hole Saw is a powerful and versatile tool that is designed to cut large, precise holes in a variety of materials, including wood, plastic, and metal. What sets this tool apart from traditional hole saws is its ability to cut larger holes with greater precision and speed, making it an invaluable addition to any construction toolkit.

This innovative tool is manufactured by a leading company in the construction industry, known for its commitment to quality and innovation. With a strong reputation for producing high-quality tools and equipment, this company has been a trusted name in the construction industry for many years.

The 180mm Hole Saw is the latest addition to the company's extensive line of cutting tools, and it is already generating a buzz among construction professionals. Its ability to cut large, precise holes with ease has made it a popular choice for builders, plumbers, electricians, and other tradespeople who rely on precise hole-cutting for their projects.

One of the key features of the 180mm Hole Saw is its durable construction, which allows it to withstand the rigors of the construction site. Made from high-quality materials, this tool is built to last, making it a reliable and long-lasting addition to any construction toolkit.

In addition to its durability, the 180mm Hole Saw is also designed for easy and efficient use. Its ergonomic design and user-friendly features make it a practical and effective tool for construction professionals. With its powerful cutting capabilities and ease of use, the 180mm Hole Saw is set to become a go-to tool for anyone in need of precise hole-cutting in their construction projects.

Furthermore, the 180mm Hole Saw is backed by the company's commitment to quality and customer satisfaction. With a dedication to providing top-notch tools and equipment, this company stands behind its products and is known for offering excellent customer support and service.

As the construction industry continues to evolve, the demand for innovative tools and equipment is higher than ever. The 180mm Hole Saw is a prime example of how cutting-edge technology is being used to meet the needs of construction professionals, providing them with the tools they need to work more efficiently and effectively.

In conclusion, the 180mm Hole Saw is a game-changer in the construction industry. With its powerful cutting capabilities, durable construction, and user-friendly design, it is set to become an essential tool for construction professionals everywhere. Backed by a leading company in the industry, this innovative tool is a testament to the ongoing evolution of construction tools and technologies. Whether used for large-scale construction projects or smaller, more intricate jobs, the 180mm Hole Saw is poised to make a lasting impact on the construction industry.

Company News & Blog

Upgraded Oscillating Saw Blades for Precision Cutting Tasks

Woodworking enthusiasts are constantly on the lookout for the latest and most innovative accessories and tools to make their projects easier and more efficient. One such product that has made a significant impact in the woodworking realm is the Wood Oscillating Saw Blades (WOSB), a versatile set of blades designed to handle a wide range of cutting tasks in the workshop.WOSB is manufactured by a company known for its expertise in creating high-quality tools and accessories for DIY enthusiasts and professional tradespeople alike. The company takes pride in its commitment to providing customers with the best products possible, backed by outstanding customer support, and WOSB is no exception.Designed to fit most multi-tools on the market, WOSB features a universal arbor that allows users to switch blades quickly and easily. Made from high-quality materials, including bi-metal and high-carbon steel, the blades are durable, long-lasting, and can withstand heavy use without breaking or dulling.The unique design of the WOSB ensures that users can make precise and accurate cuts, regardless of the angle or curvature of the material being worked on. The blades are cut on both sides, allowing them to cut in any direction, making it easier to remove damaged wood, cut intricate shapes, and create smooth edges.Whether you’re a professional woodworker or DIY enthusiast, the WOSB is an essential accessory that can help improve your efficiency and effectiveness in your workshop. From cutting, shaping, and trimming, to sanding and polishing, WOSB offers a versatile solution to handle all your woodworking needs.Aside from its cutting-edge features, the WOSB is extremely safe to use, thanks to its anti-kickback design. This feature minimizes the risk of injury caused by the tool suddenly jerking or bouncing during a cut, which can cause accidents or damage to the material being worked on.Moreover, the WOSB's precision, coupled with its ability to make clean cuts, make it the perfect choice for delicate and intricate projects such as furniture making, woodworking, and cabinetry. Many customers have praised the WOSB for helping them to achieve flawless finishes and intricate details on their projects, enhancing the overall quality and appearance of their work.In conclusion, the Wood Oscillating Saw Blades are an outstanding addition to any woodworker's arsenal of tools. The versatility, precision, and safety features of WOSB make it an ideal choice for anyone who wants to achieve excellent results with their woodworking projects. Manufactured by a company renowned for its quality and commitment to customer satisfaction, WOSB provides an excellent value for anyone looking to invest in a top-of-the-line oscillating saw blade.

Ultimate Guide to the 16-Inch Saw Blade: Everything You Need to Know

article:16-Inch Saw Blade – The Ultimate Solution for Efficient Cutting PowerAre you tired of spending countless hours cutting through tough materials? Do you need a saw blade that can deliver power and precision? Look no further than the 16-inch saw blade!This cutting-edge blade is the ultimate solution for those seeking the highest levels of cutting power. Specifically designed for heavy-duty applications, this blade is made from the highest quality materials to ensure maximum efficiency and durability.The 16-inch saw blade uses advanced technology to deliver superior cutting performance. Its design enhances performance by minimizing vibrations for an exceptionally clean and consistent cut. Precision is reached through the use of laser-cut teeth with an aggressive orientation that ensures perfect cuts every time.This saw blade performs beautifully on a variety of materials. The blade works perfectly with hardwoods, softwoods, plywood, and particleboard. It’s also perfectly suited for cutting through metals, plastics and even concrete.Made with premium carbide materials, this saw blade is designed to last and keep its sharp edge. It’s the perfect choice for those looking for a blade that can provide long-term performance. For added safety, our 16-inch saw blade is equipped with a heat-resistant non-stick coating, which prevents buildup and reduces friction, thus preventing potential hazards.If you’re looking for a reliable and efficient saw blade, look no further than our 16-inch saw blade. We pride ourselves on providing solutions that meet the highest standards of our customers. We always strive to deliver products that deliver maximum performance and long-term durability.Whether you work in construction, carpentry, or DIY projects, the 16-inch saw blade is a must-have tool in any workshop. Use it to create precise cuts for a flawless finish. Make clean and effortless cuts through a variety of materials, and turn your vision into reality.Our company, with over 20 years of experience in the industry, is committed to providing high-quality products our customers can trust. We prioritize customer satisfaction and strive to deliver the best possible experience for everyone who chooses to work with us.Our 16-inch saw blade is one of the best products we offer and we stand behind it. We are confident that you will be satisfied with the performance and durability of our saw blade. In fact, we offer a long-term guarantee against any defects in our product, so you can buy with confidence.If you’re looking for a saw blade that will deliver reliability and efficiency, look no further than the 16-inch saw blade. It’s a tool that’s specifically designed to help you get the job done right. Whether you’re a professional in the industry or an ambitious DIY enthusiast, our saw blade is the perfect tool to take your projects to the next level!In conclusion, the 16-inch saw blade is the ultimate solution for anyone looking to maximize their cutting power. Equipped with advanced technology, this blade delivers superior performance on a wide range of materials. Its aggressive teeth and laser-cut design ensure precision cuts and excellent durability. Whether you're a professional or a DIY enthusiast, our saw blade is the perfect tool to get the job done. With our 20 years of experience, we guarantee nothing but the highest quality products delivered with exceptional customer service. Choose our 16-inch saw blade today and take the efficiency and precision of your work to the next level!

Top-quality Milling Cutters and Welding Equipment Suppliers | Reviews and Product Info

Milling cutters are one of the most commonly used tools in the manufacturing industry. They are critical to the production of precision components used in various applications such as aerospace, medical, automotive, and electronic industries. Today, we'll talk about milling cutters, and specifically, CNC milling cutters. What is CNC Milling Cutter? CNC milling cutters are cutting tools used with CNC machines. CNC milling machines are computer-controlled machines that use a milling cutter to remove material from a workpiece. This type of machine allows for the creation of complex and intricate components that are impossible to achieve with conventional machines. Types of CNC Milling Cutters There are several types of CNC milling cutters available in the market, each with its unique purposes and uses. Below are some of the most popular types of CNC milling cutters: 1. Ball nose cutter A ball nose cutter is a type of end mill that is used for milling a curved surface. Its unique design allows it to create contours on a workpiece. It is commonly used in 3D modeling and CNC carving. 2. Face mill cutter A face mill cutter is used for milling flat surfaces. It is commonly used in the production of large components such as engine blocks. 3. Thread milling cutter Thread milling cutters are used for milling threads in a workpiece. They can create both external and internal threads. 4. T-slot cutter T-slot cutters are used to create T-shaped slots in a workpiece. They are commonly used in the production of machine tables. How to choose the right CNC milling cutter? Choosing the right CNC milling cutter is critical to achieving a high-quality finish on a workpiece. Here are some tips to help you choose the right milling cutter: 1. Material - Choose a milling cutter that is the right hardness for the material you are working with. For example, if you are working with steel, choose a cutter that is designed to cut through steel. 2. Geometry - The geometry of a milling cutter determines its cutting performance. Select a cutter based on its geometry to get the desired finish on your workpiece. 3. Coating - Coating plays a crucial role in the performance of a CNC milling cutter. A coated cutter will last longer and stay sharper than an uncoated one. Benefits of CNC Milling Cutters The use of CNC milling cutters has several benefits, including: 1. Increased productivity - CNC machines can produce complex components in less time than conventional machines. 2. Greater precision - CNC machines can produce components with greater accuracy than conventional machines, thanks to their ability to follow pre-programmed instructions. 3. Lower costs - CNC machines can reduce labor costs by automating the production process. Conclusion CNC milling cutters are essential tools in the manufacturing industry. They play a critical role in the production of precision components used in various applications. When selecting a CNC milling cutter, consider factors like material, geometry, and coating. The right cutter will help you achieve the desired finish on your workpiece.

Tile Installers Prefer Cement Board for Cutting Backer Board During Installation

Cutting Hardie Backer Board: Tile Installers Select Cement Board as Most Preferred Tile installation has been a crucial part of building construction, be it for homes, commercial spaces, or public buildings. A reliable backing material is essential to provide a smooth surface for tile installation, and Hardie Backer Board has been popular among tile installers for many years. However, recent surveys and reviews indicate that cement board has become the most preferred choice for tile installers when it comes to cutting backer board.Cutting Hardie Backer BoardCutting Hardie Backer Board can be a challenging task for both professional tile installers and DIY enthusiasts. While this material provides excellent hardness and durability, it can also cause excessive dust and pose health risks if not handled correctly. Moreover, cutting Hardie Backer Board requires specialized tools and expertise, making it a time-consuming and expensive process.Select Cement Board as Most PreferredIn recent surveys and reviews, tile installers have indicated that cement board has become the most preferred choice for installing backing material in tile installation projects. Cement board is a composite material that provides excellent resistance to moisture, mold, and mildew, making it an ideal choice for both indoor and outdoor tile installations. Moreover, cutting cement board is easier than cutting Hardie Backer Board, and it generates less dust, making it safer for installers and anyone nearby.Installing Hardiebacker Cement BoardInstalling Hardiebacker Cement board requires several steps, starting from measuring and cutting the material to size. The installers need to ensure a precise measurement of the tile installation area and cut the cement board accordingly, using specialized tools, such as circular saws or jigsaws. However, unlike cutting Hardie Backer Board, cutting cement board creates less dust, and the installers need not wear protective masks or respirators.Tools for CuttingWhile cutting Hardie Backer Board requires specific tools, such as carbide-tipped blades or shears, cutting cement board can be done with common household tools, such as circular saws or jigsaws. This makes the cutting process far more accessible and safer, and it reduces the time and cost needed for tile installation projects.Holes in Cement BoardCreating holes in cement board is another necessary step in tile installation projects. This process involves cutting a hole in the cement board to fit fixtures, such as sinks, pipes, or electrical outlets. Cutting holes in Hardie Backer Board can be challenging and time-consuming, requiring specialized tools and expertise. However, cutting holes in cement board is relatively simple and can be done using common household tools, such as drill bits or hole saws.ConclusionTile installation projects require a reliable backing material that can provide a smooth, moisture-resistant surface for tile installation. While Hardie Backer Board has been a popular choice for tile installers for many years, recent reviews and surveys indicate that cement board has become the most preferred choice. Cutting Hardie Backer Board requires specialized tools and expertise, making it a time-consuming and expensive process. In contrast, cutting cement board is easier and generates less dust, making it safer for installers and anyone nearby. Moreover, cutting cement board can be done using common household tools, reducing the cost and time needed for tile installation projects.

Efficient Stainless Steel Cutting Saw Blades: Boost Your Cutting Experience

Stainless Steel Cutting Saw Blade Revolutionizes Metalworking IndustryThe global metalworking industry is undergoing a tremendous transformation with the introduction of the revolutionary stainless steel cutting saw blade. This cutting-edge tool is formulated to provide unparalleled precision, efficiency, and durability, significantly impacting various sectors such as construction, manufacturing, and automotive.Developed by a leading manufacturer in the metalworking industry, this innovative saw blade has already gained immense popularity due to its outstanding performance and exceptional quality. The company, with years of experience and expertise in the field, has successfully integrated advanced technology and rigorous research to produce a product that surpasses all expectations.The stainless steel cutting saw blade boasts several key features that set it apart from conventional cutting tools. Its expertly designed teeth and cutting edge ensure optimal cutting efficiency and reduce the occurrence of burrs and chipping. This groundbreaking design enables smooth, clean cuts, allowing metalworkers to achieve high-quality results while minimizing material wastage.Furthermore, the saw blade's unique composition enhances its durability and longevity. The manufacturer has utilized premium-grade stainless steel combined with high-performance alloys, resulting in a blade that is resistant to wear and corrosion. This longevity translates into cost savings for businesses as frequent blade replacements will be significantly reduced.One of the standout aspects of this stainless steel cutting saw blade is its versatility. It is compatible with a wide range of industrial machines, enabling metalworkers to easily integrate it into their existing equipment without the need for substantial modifications. Moreover, its adaptability to various cutting conditions - including different types and thicknesses of stainless steel - makes it an indispensable tool in the metalworking industry.The impact of this innovative saw blade extends beyond its performance. The manufacturer has ensured that the production process adheres to strict environmental standards, taking significant steps towards sustainability. By using eco-friendly materials and adopting sustainable manufacturing practices, the company contributes to reducing the industry's carbon footprint.As the metalworking industry is highly competitive, heightened productivity is crucial for companies to maintain a leading edge. The introduction of the stainless steel cutting saw blade addresses this need, as it results in substantial time savings during the cutting process. Metalworkers can now complete jobs in a shorter time frame, allowing for increased efficiency and faster turnaround, which ultimately boosts overall productivity.The stainless steel cutting saw blade has received widespread acclaim from metalworking professionals globally. Industry experts have praised its ability to deliver consistent cutting performance, allowing for precise and accurate cuts even in highly demanding applications. This precision is especially valuable in industries such as aerospace, where the highest level of accuracy and quality is essential.Looking towards the future, the manufacturer remains committed to advancing their saw blade technology. They are continuously investing in research and development to explore new materials, refine designs, and enhance the blade's performance. This dedication to innovation ensures that the stainless steel cutting saw blade will continue to exceed industry expectations and lead the way in metalworking advancements.In conclusion, the introduction of the stainless steel cutting saw blade has revolutionized the metalworking industry. Its unparalleled precision, efficiency, and durability have made it an indispensable tool for metalworkers in various sectors. With its ability to deliver high-quality cuts, reduce material wastage, and enhance productivity, this cutting-edge tool is redefining metalworking practices worldwide. As the manufacturer continues to innovate, the industry can expect further advancements that will shape the future of metalworking.

Flexible Sandpaper Sheets for Hand Sanding on Multiple Surfaces

When it comes to woodworking, one of the most important steps in achieving a smooth and polished finish is sanding. Sanding can help to remove rough spots on the wood, and also prepare the surface for the application of stains or finishes. In order to achieve the best results, it’s important to use the right type of sandpaper.One option for sanding is using sheet sandpaper. Sheet sandpaper comes in a variety of grits, from coarse to fine, and is commonly used on wood and many solid surface materials. Often sold in packs of multiple sheets, it’s an affordable and effective solution for hand sanding.One great option for sheet sandpaper is (Need to remove brand name). These sandpaper sheets have excellent fold ability, which means they can be easily folded and manipulated for hand sanding in tight spaces or corners. With their durable construction, they are perfect for sanding between coats, preparing surfaces for finishing, or removing light scratches and imperfections.When using sheet sandpaper on wood, it’s important to start with the correct grit for your project. For rough sanding or removing paint, a coarse grit such as 80 or 100 will be best. For smoothing out scratches and preparing for finishing, a medium grit such as 120 or 150 will be needed. Finally, for achieving a smooth and polished finish, a fine grit of 220 or 320 will be necessary.Another tool that can be used for sanding in woodworking is scroll saw sanding blades. These blades are specifically designed for use with a scroll saw, and can be used for sanding tight curves and angles that are difficult to reach with traditional sandpaper.When using scroll saw sanding blades, it’s important to choose the right blade for your project. The thickness and width of the blade will depend on the curvature of the project, as well as the type of wood being used. It’s important to also match the grit of the sanding blade to the grit of the sandpaper being used, in order to achieve a uniform finish.While both sheet sandpaper and scroll saw sanding blades are helpful tools for achieving a polished finish in woodworking, it’s important to take care when sanding. Always wear personal protective equipment such as goggles and a dust mask to protect your eyes and lungs from dust and debris. Additionally, take care to sand evenly and in the same direction as the wood grain, in order to avoid scratching or gouging the wood surface.In conclusion, when it comes to sanding in woodworking, it’s important to use the correct tools and techniques in order to achieve the best results. Whether using sheet sandpaper for hand sanding, or scroll saw sanding blades for tight angles and curves, taking the time to sand carefully and thoroughly can make a big difference in the final product. Remember to always wear protective gear, use the right grit for your project, and take care to sand in the direction of the wood grain.

Discover the High-Quality 14-Inch Chop Saw Blade for Efficient Cutting

(title)New Advanced Chop Saw Blade Promises Enhanced Cutting Precision and Durability(date)(city)The cutting-edge world of construction and manufacturing has seen a significant technological advancement with the introduction of the latest innovation in the form of the 14 Chop Saw Blade. This state-of-the-art tool, developed by an industry-leading company, is set to revolutionize the cutting process by providing enhanced precision, durability, and efficiency.The 14 Chop Saw Blade, a result of years of research and development, has been carefully engineered to meet the growing demands of professionals in various fields, including construction, metalworking, and woodworking. Its cutting-edge design ensures accurate and clean cuts, making it an indispensable tool for both professionals and DIY enthusiasts.One of the key features of the 14 Chop Saw Blade is its exceptional cutting precision. Equipped with cutting-edge technology, this blade guarantees clean and precise cuts with minimal effort. Whether it is cutting through metal, wood, or other materials, this tool promises accuracy, resulting in reduced wastage and increased efficiency on the job site.Durability is another standout characteristic of the 14 Chop Saw Blade. Constructed using high-quality materials, this blade is designed to withstand rigorous usage and last longer than traditional blades. Its robust build ensures that it remains sharp for an extended period, reducing the need for frequent replacements. This not only saves time and money but also increases productivity by ensuring uninterrupted work.The 14 Chop Saw Blade also boasts a unique tooth design that contributes to its superior performance. With specially engineered teeth, this blade can effortlessly glide through the toughest of materials, providing a faster and smoother cutting experience. It minimizes vibration, reducing the strain on the user and enhancing overall user comfort.Safety is a paramount concern in any cutting operation, and the 14 Chop Saw Blade addresses this concern with its innovative design. Equipped with special anti-kickback features, this blade ensures that any potential kickbacks are minimized, providing a safer working environment for users. This feature greatly reduces the risk of accidents and injuries, making it an ideal choice for professionals and individuals alike.As a company committed to delivering exceptional quality tools, the manufacturer of the 14 Chop Saw Blade prides itself on its attention to detail and customer satisfaction. With a reputation for producing top-of-the-line products, this company has earned the trust and loyalty of professionals from various industries. Their commitment to continuous improvement guarantees a product that exceeds expectations and delivers unparalleled performance.In addition to its outstanding features, the 14 Chop Saw Blade is also compatible with a range of chop saws available in the market. Its universal design ensures that professionals and DIY enthusiasts can easily integrate it into their existing equipment without any hassle.In conclusion, the introduction of the 14 Chop Saw Blade marks a significant leap forward in the world of cutting technology. With its enhanced cutting precision, durability, and safety features, this tool offers professionals and DIY enthusiasts an unparalleled cutting experience. Backed by a reputable manufacturer known for its commitment to quality, this blade is set to redefine the standards of precision cutting. With the 14 Chop Saw Blade, the future of construction and manufacturing is bound to become more accurate, efficient, and productive.

102mm Diamond Grit Holesaw for Ceramic Tiles, Fibre Cement and Soft Stone - New and Unused This high-quality 102mm Diamond Grit Holesaw is designed for cutting through an array of materials such as glass, tiles, laminates, fibre glass, and hard plastic. With a cutting depth of 25mm, it is ideal for those looking to create precise holes in their projects. Brand new, unused, and in its original packaging, this tool comes with a tax invoice.

Sutton Tools Diamond Grit Holesaw: The Perfect Solution for Cutting Ceramic Tiles, Fibre Cement and Soft StoneAre you looking for a tool that can help you cut through tough materials such as ceramic tiles, fibre cement, and soft stone with ease? Look no further than the Sutton Tools Diamond Grit Holesaw. This 102mm holesaw is designed with diamond grit which ensures that it stays sharper for longer, and is capable of cutting through various materials such as glass, tiles, laminates, fibre glass, and hard plastic. It is perfect for those who need to cut holes in bathroom or kitchen tiles, or any other tough material around the house. The Sutton Tools 102mm Diamond Grit Holesaw has a cutting depth of 25mm. This means that it can easily cut through thicker materials than other holesaws, making it a great tool for professionals who need to cut through different thicknesses of materials on a regular basis. What sets this holesaw apart from others is its ability to cut through fibre cement. This durable material is used in many construction sites and is known for its strength and durability. Cutting through fibre cement can be a tough task, but with the Sutton Tools Diamond Grit Holesaw, it is made easy and effortless. The Sutton Tools Diamond Grit Holesaw is brand new, has never been used, and is in its original packaging with a tax invoice. The part number for this holesaw is H115 1020. You can be assured of its quality and durability with Sutton Tools' reputation for producing high-quality tools that are built to last. In conclusion, the Sutton Tools Diamond Grit Holesaw is the perfect solution for those who need to cut through tough materials such as ceramic tiles, fibre cement, and soft stone. It is designed with diamond grit which ensures that it stays sharper for longer and has a cutting depth of 25mm, making it ideal for cutting through various thicknesses of materials. It is perfect for professionals who need to cut through different thicknesses of materials on a regular basis. Get your hands on this tool today and make cutting through tough materials a breeze! Keywords: Cement Hole Saw, Ceramic Tiles, Fibre Cement, Soft Stone, Sutton Tools, Diamond Grit Holesaw, Cutting Depth, Sharpness.

Flat-Top Ripping Blades: The Go-To Tool for Sculptural Woodwork

Sculptural woodwork, a form of woodworking that involves the carving and shaping of wood to create unique works of art, requires precision and skill. To achieve professional results, selecting the right tools is crucial, and the blade used in a table saw is no exception.Chris Wong, a renowned sculptural woodworker, relies heavily on his Freud 24-tooth Heavy Duty Rip Blade (LM72M010) for his projects. In fact, he estimates that it is installed in his table saw 90% of the time. What makes this blade standout in the market is its flat-top ripping feature, which outperforms other blades in cutting lumber and producing clean and accurate edges.The blade has 24 teeth that measure 0.126 inches wide, specifically designed for ripping lumber. The ground flat-top feature ensures that the teeth are all of equal height and aligned perfectly with one another, creating a flat and even surface on top of the blade. This makes it ideal for cutting wood horizontally, producing a smooth, even cut along the entire length of the workpiece.Moreover, the blade’s forward pitch angle contributes significantly to its effectiveness in ripping. The angle creates a hook that enables it to slice through the wood fibers with ease, producing accurate cuts and minimizing the risk of chips or splinters.Wong, who has been using the Freud 24-tooth Heavy Duty Rip Blade for years, attests to its durability and quality. The blade remains sharp even after repeated use, reducing the need for frequent replacements. Additionally, the blade’s design reduces the strain on the motor and prolongs the lifespan of both the blade and table saw.Freud is a leading manufacturer of cutting tools and accessories, committed to producing the highest quality products. Their blades are engineered to deliver exceptional performance, durability, and precision. They offer a wide range of blades, including a selection of flat-top ripping blades for woodworking.Sculptural woodwork, like any other craft, requires a keen attention to detail. Choosing the right blade is essential in pushing the boundaries of traditional woodworking and producing innovative designs. The Freud 24-tooth Heavy Duty Rip Blade (LM72M010) is a must-have for any sculptural woodworker who wants to create exceptional work.In conclusion, the Freud 24-tooth Heavy Duty Rip Blade is the king of sculptural woodwork. Equipped with its flat-top ripping feature, precise ground teeth, and forward pitch angle, it’s the perfect tool for creating accurate cuts and smooth edges. Along with Freud's commitment to producing high-quality tools, this blade is sure to deliver exceptional performance and longevity, making it an excellent investment for any woodworker.

Optimize Your Cutting Efficiency with a High-Quality Hole Saw Cutter

Title: Innovative Hole Saw Cutter Revolutionizes Cutting Efficiency in Various IndustriesIntroduction:In today's fast-paced world, industries and professionals constantly seek cost-effective and efficient solutions that enhance productivity and deliver high-quality results. This pursuit has led to the development of exceptional tools such as the revolutionary Hole Saw Cutter. Led by its commitment to excellence and innovation, our company has redefined the cutting process across multiple sectors, making tasks more convenient and delivering unmatched precision.Changing the Game:The Hole Saw Cutter, redefining the art of cutting, is designed to effortlessly create holes in various materials, including wood, plastic, metal, and drywall. With its advanced engineering, cutting-edge design, and superior functionality, this tool has quickly become an essential component in industries such as construction, plumbing, electrical, and woodworking.Unparalleled Efficiency:Unlike traditional cutting methods that often require different tools for different materials, the Hole Saw Cutter simplifies the process by allowing professionals to work with ease and precision, regardless of the material they are tackling. This versatile tool eliminates the need for separate tools, saving time and increasing efficiency on the job site.Advanced Features:The Hole Saw Cutter boasts several innovative features that set it apart from conventional cutting tools. 1. Enhanced Durability: Manufactured using high-quality materials, this cutter ensures longevity and enduring performance, significantly reducing replacement costs for businesses.2. Efficient Design: The design of the Hole Saw Cutter incorporates an optimized blade design, enabling smooth and effortless cutting through various materials. Additionally, its ergonomic handle provides a comfortable grip and reduces user fatigue during prolonged operations.3. Versatile Hole Sizes: With an extensive range of interchangeable hole sizes available, this cutter allows professionals to adapt to different project requirements effortlessly.4. Safety Features: The Hole Saw Cutter has been engineered with safety in mind. It includes a built-in safety mechanism, preventing accidental slips or disengagement during operation, ensuring user protection.Multiple Applications:Thanks to its adaptability, the Hole Saw Cutter finds wide-ranging applications across diverse industries.1. Construction: Whether it's for creating openings for electrical outlets, plumbing connections, or ventilation systems, this cutter provides accurate and efficient hole-cutting in various construction materials.2. Plumbing: The Hole Saw Cutter is instrumental in pipe fitting applications, swiftly cutting the necessary holes for fixtures, joints, and connections.3. Electrical: Professionals in electrical installations rely on the Hole Saw Cutter to create openings for wires, switches, and outlets with precision and ease.4. Woodworking: Craftsmen and carpenters can now accomplish intricate cutting tasks in wooden surfaces, enabling them to expand their creative possibilities with this versatile tool.Investing in Efficiency:The Hole Saw Cutter serves as a valuable asset for businesses seeking enhanced productivity, reduced costs, and optimized operations. The innovative technologies integrated into this tool ensure increased efficiency and improved results, establishing the company as a reliable partner in various industries.Conclusion:As industries continue to evolve and strive for excellence, the Hole Saw Cutter emerges as an exceptional tool, combing convenience, precision, and efficiency. With its cutting-edge design, durability, safety features, and versatile applications, this revolutionary tool deserves its place as a game-changer in various industries. Our company stands proud as the driving force behind this innovation, contributing to the growth and success of professionals across the globe.