Ultimate Guide to Circular Saw Blades: Everything You Need to Know

Title: Cutting-Edge Circular Saw Blades Revolutionize Woodworking IndustryIntroduction:In a world where quality and precision matter, {} continues to soar as the leading manufacturer of advanced circular saw blades. With an unwavering commitment to innovation and excellence, the company has propelled itself to the forefront of the woodworking industry. Recognized globally for their superior performance and longevity, these state-of-the-art circular saw blades have revolutionized woodworking, enabling professionals to achieve unparalleled precision, speed, and efficiency.I. Unraveling the Intricacies of {} Circular Saw BladesThe secret behind the immense success of {} lies in their relentless pursuit of perfection. Committed to delivering the finest craftsmanship, {} utilizes cutting-edge technology and the highest quality materials to engineer circular saw blades that are synonymous with reliability, sharpness, and durability.1. Superior Construction and Materials{} Circular Saw Blades are meticulously crafted from premium carbide and steel alloy, ensuring exceptional strength and resilience. This revolutionary combination guarantees maximum precision and durability, even when cutting through the toughest and most challenging materials.2. Innovative Tooth GeometryFeaturing a specially designed tooth geometry, {} Circular Saw Blades minimize resistance while optimizing cutting performance. The precise tooth angles and gullet designs ensure smooth and effortless cuts, eliminating tear-out and leaving a flawless finish on the workpiece.3. Enhanced Heat DissipationThe blades incorporate advanced heat dissipation technology, thereby minimizing heat build-up during prolonged usage. This innovative feature not only extends the blade's lifespan but also enhances the overall cutting efficiency, reducing the risk of blade-dulling due to excessive heat.II. Unmatched Performance and VersatilityWith a relentless focus on performance, {} has engineered circular saw blades that surpass industry standards, setting new benchmarks in precision and versatility.1. Precision Cutting{} Circular Saw Blades consistently provide razor-sharp precision, enabling woodworkers to create intricate designs and achieve outstanding results every time. Whether cross-cutting, ripping, or making complex bevel cuts, these blades effortlessly slice through materials, ensuring exceptional accuracy without compromising on speed.2. Versatility in ApplicationDesigned to cater to the diverse needs of woodworking professionals, {} Circular Saw Blades excel across a vast range of applications. From fine woodworking to construction sites, these blades effortlessly handle a variety of materials, including hardwood, softwood, plywood, chipboard, and even composite materials.III. Testament to Global Recognition and TrustThe reputation of {} Circular Saw Blades extends far beyond their superior performance. The unwavering trust they have garnered from industry professionals worldwide speaks volumes about their exceptional quality and reliability.1. Positive Feedback from ProfessionalsWoodworking professionals spanning various disciplines express supreme confidence in the performance of {} Circular Saw Blades. Their testimonials highlight the blades' exceptional cutting speed, accuracy, and ability to withstand heavy use with minimal wear and tear.2. Awards and AccoladesThe relentless pursuit of excellence has led {} to receive numerous prestigious awards and accolades within the woodworking industry. These recognitions not only serve as a testament to their commitment to quality but also establish {} as the go-to brand for outstanding circular saw blades.IV. Investing in the Future: Continuous Innovation and Customer Satisfaction{} strives to remain ahead of the curve by constantly investing in research and development. The company's commitment to innovation ensures that customers have access to the most advanced circular saw blades, enabling them to take their woodworking projects to unprecedented levels of precision and efficiency.1. Ongoing Research and Development{} maintains an R&D department dedicated to exploring emerging technologies and materials to further enhance their circular saw blades. This continuous investment in innovation guarantees that customers always have access to cutting-edge tools that meet their evolving needs.2. Unparalleled Customer Support{} places customer satisfaction as a top priority, offering comprehensive after-sales support and product consulting services. Their team of experts assists customers in selecting the ideal circular saw blades for their requirements, ensuring that they achieve optimum results with utmost efficiency.Conclusion:With an unwavering commitment to perfection and continuous innovation, {} Circular Saw Blades have redefined the woodworking industry. The exceptional performance, versatility, and trust they inspire in professionals around the globe have solidified their position as the leading brand in the market. Whether it is crafting intricate works of art or executing large-scale construction projects, {} Circular Saw Blades are the epitome of excellence, enabling woodworkers to achieve precision and efficiency like never before.

Read More

High-Quality Diamond Cutting Discs for Angle Grinders Available Now!

article about the benefits of using diamond cutting discs for angle grinders in various industriesThe use of angle grinders has become a common practice across different industries around the world. From construction to manufacturing, these tools have become increasingly vital in the speedy and efficient completion of tasks. They help to cut metals, concrete, tiles, and other materials with precision, accuracy, and ease.However, the quality of the cutting discs used in angle grinders plays a critical role in the overall efficiency and effectiveness of these tools. In this regard, Diamond Cutting Discs for Angle Grinders are emerging as the ideal choice for businesses that need reliable, high-quality cutting tools.Leading manufacturers that specialize in diamond cutting discs have produced a wide range of products, each designed for specific applications. Their cutting-edge technology has made them a popular choice for businesses across various sectors. Here are some benefits of using diamond cutting discs in various industries.Construction IndustryIn the construction industry, high-quality cutting discs are incredibly important, especially when cutting materials like concrete, brick, and ceramic tiles. The diamond cutting disc from the company {brand name} is designed to be durable and reliable, allowing it to cut through hard materials like concrete and stone.These cutting discs come in different sizes, covering a range of grinder types. The use of diamond cutting discs ensures that even hard materials can be cut with precision, regardless of size or thickness, thereby reducing waste and increasing efficiency. Diamond cutting discs with thin cutting edges of as little as 1.0 mm can even cut rebar or HSLA steel reinforcing bars, a task which is difficult with many other cutting discs.Manufacturing IndustryIn the manufacturing industry, diamond cutting discs are critical components in ensuring precision cuts. Diamond cutting discs from {brand name} are typically designed to have a long lifespan and withstand extreme temperatures, enabling them to be used in a range of applications without failure. This feature is particularly useful in manufacturing plants where long hour work shifts are often observed.The range of sizes and shapes available has allowed businesses to achieve the specific cuts they require on different products and materials. Likewise, diamond cutting discs can achieve smoother finishes on metals compared to other cutting solutions.Automotive and Aerospace IndustriesPrecision in the automotive and aerospace industries plays a significant role in ensuring the safety and reliability of vehicles and aircraft. The use of diamond cutting discs has made it possible for businesses in these industries to achieve precise cuts on different materials.Diamond cutting discs designed to cut through aluminum and titanium alloys ensure there are no micro-fractures, which can be dangerous and expensive to repair. These discs also provide a smooth finish, which is essential for welding together different sections of metal.The Final VerdictDiamond cutting discs for angle grinders are an innovative solution for businesses in different industries that require precision cuts on different materials. The use of these discs is growing in popularity due to their durability, precision and reliability in a wide range of cutting applications.Moreover, the efficiency gains and cost savings that come with the use of diamond cutting discs make them a smart investment for businesses looking to streamline their operations and enhance productivity.In conclusion, the company {brand name} produces diamond cutting discs that have revolutionized the way businesses think about cutting materials. With their precision, reliability, and durability, their range of diamond cutting discs is a popular choice among industries ranging from construction to aerospace.

Read More

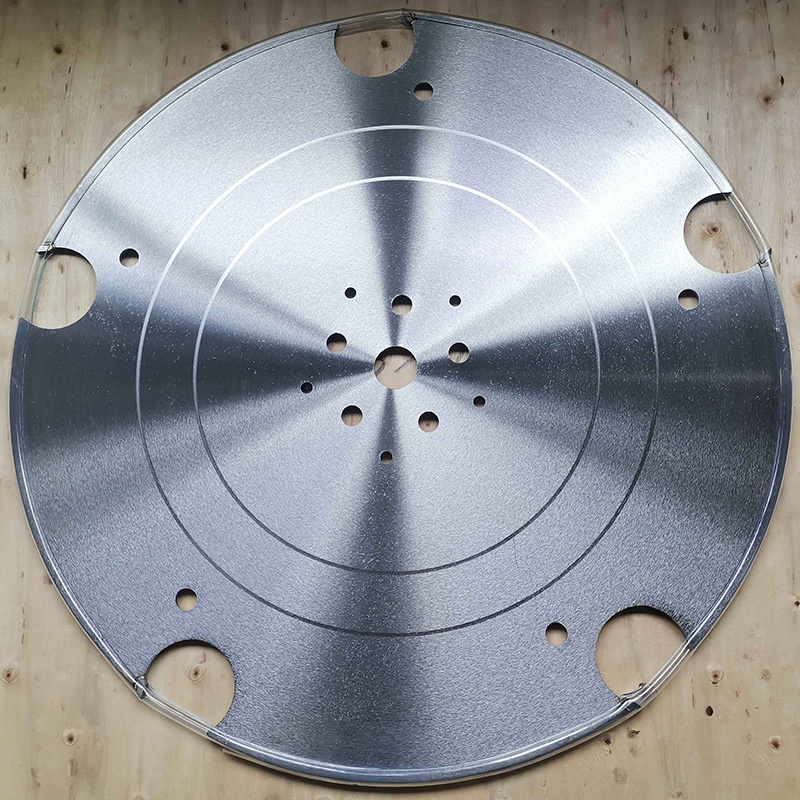

Stainless Steel Saw Blade for Accurate and Efficient Cutting

Stainless Steel Cutting Saw Blade Revolutionizes Metalworking IndustryThe metalworking industry has long been in need of an innovative and efficient solution for stainless steel cutting. With the advent of the revolutionary Stainless Steel Cutting Saw Blade, metal fabricators can now expect increased efficiency, reduced costs, and enhanced precision in their operations. This state-of-the-art saw blade has been developed by an industry-leading company dedicated to providing cutting-edge tools for the metalworking sector.Stainless steel cutting has historically been a challenging process. The hardness and density of stainless steel make it one of the most difficult materials to work with. Traditional cutting methods often resulted in slow production rates, increased expenses, and compromised precision. Manufacturers were desperately seeking a solution that would streamline the cutting process and deliver exceptional results.Recognizing this need, the visionary team at the company invested significant time and resources into developing an advanced cutting saw blade specifically designed for stainless steel. After extensive research and development, they successfully engineered a cutting-edge product that surpassed all expectations.The Stainless Steel Cutting Saw Blade boasts a range of cutting-edge features that set it apart from conventional blades. One of its key attributes is its unique tooth design, which ensures optimal cutting performance. The teeth are precisely engineered to smoothly penetrate the hardness of stainless steel, reducing friction and heat generation. This not only prolongs the lifespan of the blade but also enhances the precision of the cut.Additionally, the blade is constructed using high-quality stainless steel alloy, which further enhances its cutting capabilities and ensures durability. This allows metal fabricators to achieve clean, accurate, and burr-free cuts, greatly reducing the need for excessive finishing work.The company’s commitment to innovation and customer satisfaction is further underscored by the blade's compatibility with a wide range of sawing machines. Whether used on automatic, semi-automatic, or manual sawing machines, this versatile blade delivers consistent cutting performance, regardless of the scale or complexity of the project.Beyond the blade itself, the company has also prioritized user safety and convenience. The Stainless Steel Cutting Saw Blade comes with a comprehensive set of safety features that mitigate the risk of accidents during operation. Robust safety guards, anti-kickback mechanisms, and ergonomic handles are just some of the standards implemented in the design to ensure the utmost protection for the user.With its exceptional performance and user-friendly features, the Stainless Steel Cutting Saw Blade has already garnered considerable attention within the metalworking industry. Early adopters of the technology have reported significantly higher productivity rates, reduced material waste, and improved overall quality in their stainless steel cutting operations.The company's commitment to quality extends beyond the product itself and encompasses the entire customer experience. Their dedicated customer support team ensures that clients receive thorough training on the proper handling and maintenance of the blade. Additionally, the company offers comprehensive technical support, readily available spare parts, and a range of supplementary accessories to enhance the performance of the saw blade.As the metalworking industry evolves, so does the need for innovative tools and technologies. With the introduction of the Stainless Steel Cutting Saw Blade, the company has revolutionized the way stainless steel is cut, setting a new industry standard. Through their pioneering research and commitment to excellence, they have empowered metal fabricators worldwide to achieve unparalleled efficiency, precision, and cost-effectiveness in their operations.In conclusion, the Stainless Steel Cutting Saw Blade represents a remarkable advancement within the metalworking industry. Its cutting-edge technology has eliminated the long-standing challenges associated with stainless steel cutting, delivering exceptional results to metal fabricators. As this revolutionary saw blade continues to gain traction within the industry, it is poised to become an indispensable tool for every metalworking professional aiming to elevate their operations to new heights of efficiency and precision.

Read More

Discover the Versatile 24mm Hole Saw - Your Perfect Cutting Tool!

[Title]Innovative 24mm Hole Saw Revolutionizes Precision Cutting in the Construction Industry[Subtitle]Introducing a game-changing tool that enhances efficiency and accuracy for professional contractors[Date][City], [State] – [Date][Introduction]In today's fast-paced construction industry, professionals constantly strive to find tools and equipment that enhance their precision and efficiency. This pursuit has led to the advent of the 24mm Hole Saw, an innovative cutting tool that is set to revolutionize precision cutting. Developed by a leading manufacturer in the industry, this game-changing product promises to bring a new level of accuracy and ease to contractors' work.[Background]With a rich history spanning over two decades, the manufacturer behind the 24mm Hole Saw has established itself as a trusted name in the construction equipment market. Known for their commitment to quality and delivering products that meet and exceed industry standards, the company has consistently delivered innovative tools that contribute to the success of construction projects worldwide.[Product Overview]The 24mm Hole Saw is the latest addition to the manufacturer's impressive lineup of cutting tools. This state-of-the-art device combines cutting-edge technology with superior design to provide unparalleled performance. With a focus on precision, durability, and ease of use, this tool has been meticulously engineered to meet the rigorous demands of professional contractors.[Precision Redefined]One of the standout features of the 24mm Hole Saw is its exceptional precision. With a cutting diameter of 24mm, this tool effortlessly creates perfectly round holes with surgical precision. This level of accuracy ensures that contractors can work efficiently, minimizing the need for adjustments or rework, ultimately saving both time and money.[Durability and Longevity]Constructed from high-grade materials, the 24mm Hole Saw boasts exceptional durability and longevity. Designed to withstand the harshest conditions on-site, this tool maintains its cutting edge even in the face of heavy use. Contractors can rely on its robustness for multiple projects, making it a cost-effective investment for their toolbox.[Ease of Use]Recognizing the importance of usability in the construction industry, the 24mm Hole Saw has been ergonomically engineered for maximum comfort and efficiency. Its lightweight design reduces operator fatigue and allows for extended use without compromising performance. Additionally, the tool's intuitive operation ensures that users of all skill levels can achieve professional-grade results effortlessly.[Wide Range of Applications]The versatility of the 24mm Hole Saw makes it an indispensable tool for various applications in the construction industry. From electrical and plumbing installations to woodworking and general carpentry, this cutting-edge technology empowers contractors to take on a diverse array of projects with confidence and precision.[Conclusion]As the construction industry continues to evolve, the need for advanced tools and equipment becomes increasingly important. The introduction of the 24mm Hole Saw represents a significant milestone in meeting these demands. With its unparalleled precision, durability, and ease of use, this innovative tool is set to revolutionize professional contractors' approach to precision cutting. The manufacturer's commitment to excellence and the industry's needs ensures that the 24mm Hole Saw will play a pivotal role in shaping the future of construction.

Read More

Ultra-Thin 115mm Metal Cutting Blade Disc for Steel and Stainless Steel - Pack of 20

The Importance of Using High-Quality 115mm Metal Cutting DiscsWhen it comes to metal cutting, using a high-quality cutting disc is crucial for achieving clean and precise cuts. One such cutting disc that has gained popularity among professionals and DIY enthusiasts is the 115mm metal cutting disc.The 115mm metal cutting disc is a circular blade that is designed to cut through tough materials such as steel and stainless steel. It is available in various thicknesses, with 1mm being the most popular thickness for ultra-thin cuts. The disc has a diameter of 115mm, which is compatible with most 115mm angle grinders.One of the key advantages of using the 115mm metal cutting disc is its speed and efficiency in cutting through metal. With a maximum RPM of 13,300, it can quickly and easily cut through even the thickest of metals. Its ultra-thin design also means that it generates less heat during cutting, which helps to prevent warping, distortion, and discoloration of the metal.Another advantage of the 115mm metal cutting disc is its durability. Made from high-quality stainless steel metal, it is designed to withstand the rigors of heavy-duty cutting. It resists wear and tear, and can last up to 30% longer than standard cutting discs.When it comes to safety, the 115mm metal cutting disc is designed to reduce the risk of accidents. Its ultra-thin design means that there is less chance of kickback or snagging, while its reinforced construction enhances its stability and reduces the risk of breakages.Overall, the 115mm metal cutting disc is an essential tool for anyone who needs to cut through metal. Its speed, efficiency, durability, and safety features make it a must-have for professionals and DIY enthusiasts alike. Whether you are cutting through steel, stainless steel, or other tough metals, using a high-quality 115mm metal cutting disc is essential for achieving clean and precise cuts. To conclude, if you are looking for a reliable and efficient tool for metal cutting, 115mm metal cutting discs are the perfect choice for you. So, whether you are a professional or a DIY enthusiast, invest in high-quality cutting discs to achieve the best results.

Read More

How to Sharpen Circular Saw Blades Like a Pro

Title: Innovative Circular Saw Grinder Revolutionizes the Woodworking IndustryIntroduction:In today's competitive world, efficiency and precision are paramount in every industry. The woodworking industry, in particular, relies heavily on cutting-edge technology that enhances productivity and quality. In a groundbreaking development, an industry-leading company has unveiled their latest innovation, a Circular Saw Grinder (brand name removed), that promises to revolutionize the woodworking sector.Body:1. Overview of the Circular Saw Grinder:The Circular Saw Grinder, developed by a renowned company with years of experience in the field, presents a game-changing solution for professional woodworkers and artisans. This state-of-the-art grinder combines advanced technology, unparalleled craftsmanship, and user-friendly features to elevate the sharpening and maintenance of circular saw blades to new heights.2. Key Features and Functionality:The Circular Saw Grinder boasts a wide range of cutting-edge features that significantly enhance its performance and usability. From ergonomic design to advanced automation, here are some of the key features:2.1. Ergonomic Design: The grinder is meticulously designed to ensure optimal user comfort, enabling long hours of operation without fatigue. Its user-friendly interface makes it accessible even for less experienced woodworkers.2.2. Precision Sharpening: The grinder offers precise and consistent sharpening of circular saw blades, ensuring accurate cuts and reducing material waste. The innovative grinding mechanism guarantees uniform and perfect edges every time.2.3. Automated Operation: Integrated automation simplifies the grinding process, allowing woodworkers to save time and effort. The grinder's intuitive controls enable professionals to quickly and easily set up and operate the machine, reducing downtime and maximizing productivity.2.4. Safety Measures: The Circular Saw Grinder prioritizes safety with various built-in mechanisms to prevent accidents and injuries. Safety guards, automatic shutdown features, and emergency stop buttons have been incorporated to protect users and provide peace of mind.3. Advantages and Benefits:The introduction of the Circular Saw Grinder brings with it a myriad of advantages and benefits for woodworkers and the woodworking industry as a whole:3.1. Increased Efficiency: By automating and streamlining the sharpening process, the grinder significantly reduces downtime, allowing woodworkers to spend more time on their craft.3.2. Improved Precision: The grinder's consistent sharpening capabilities ensure more accurate cuts, resulting in high-quality finished products. This enhances the reputation and standing of woodworking businesses.3.3. Cost-effective Solution: The Circular Saw Grinder's longevity and durability contribute to its cost-effectiveness. With extended machine life and reduced need for blade replacements, it saves woodworkers money over time.3.4. Sustainable Manufacturing: The grinder's prolonged blade lifespan reduces waste, promoting sustainable woodworking practices. This aligns with the growing demand for eco-friendly production methods.4. Market Impact and Future Prospects:The introduction of the Circular Saw Grinder is a significant milestone in the woodworking industry. Woodworkers and professionals in the sector now have access to cutting-edge technology that will improve their efficiency and overall craftsmanship. It is expected that this innovative solution will disrupt the market, leading to increased competitiveness and driving the industry towards further advancements.In conclusion, the Circular Saw Grinder, developed by a leading woodworking company, revolutionizes the sharpening and maintenance of circular saw blades. With its ergonomic design, precision sharpening capabilities, automation, and safety features, it offers numerous advantages to woodworkers. The impact of this innovative product on the woodworking industry is expected to be far-reaching, fostering increased efficiency, precision, and sustainability in the sector.

Read More

Exploring BDSM Therapy: Intense Anal Training and Fist Therapy in the Fetish Institute (Part 1 of 4)

Read More

6-3/16 Inch Jamb Saw Blade for Effortless Cutting of Door Frames

Read More

20 x 115mm Ultra Thin Metal Cutting Blade Disc for Steel and Stainless - 1mm Thickness

115mm Metal Cutting Discs: The Ultimate Solution for Metal CuttingMetal cutting has always been a tricky job, but with the introduction of 115mm metal cutting discs, things have become much easier. These ultra-thin discs are designed specifically for cutting through metal, steel and stainless steel, making them a popular choice among professional tradespeople and DIY enthusiasts alike. The 115mm metal cutting disc has a diameter of 4.5 inches and a thickness of 1mm, making it one of the thinnest discs available on the market. The thinness of the disc is a key factor in its ability to cut through metal with such precision and ease. The 115mm metal cutting disc is also suitable for use with all 115mm angle grinders, making it a versatile tool for any metal cutting job.The maximum revolutions per minute (RPM) for the 115mm metal cutting disc is 13,300. This high RPM makes the disc ideal for use in a range of different applications. Whether you are cutting through thin sheets of metal or thicker steel and stainless steel, the 115mm metal cutting disc will get the job done quickly and efficiently.One of the most impressive features of the 115mm metal cutting disc is its cost-effectiveness. At only 0.32 pence per disc, these discs offer great value for money, especially when compared to other cutting solutions on the market.When it comes to cutting through metal, safety is of the utmost importance. The 115mm metal cutting disc is designed with safety in mind, featuring a reinforced structure that adds extra strength and stability to the disc. This added strength reduces the chances of the disc breaking or shattering during use, helping to keep the operator safe and the work environment hazard-free.In conclusion, the 115mm metal cutting disc is a must-have tool for anyone who needs to cut through metal. Its ultra-thin design, cost-effectiveness, high RPM, and safety features make it the ultimate solution for all metal cutting needs. So, whether you are a professional tradesperson or a DIY enthusiast, make sure to add the 115mm metal cutting disc to your tool kit today.

Read More