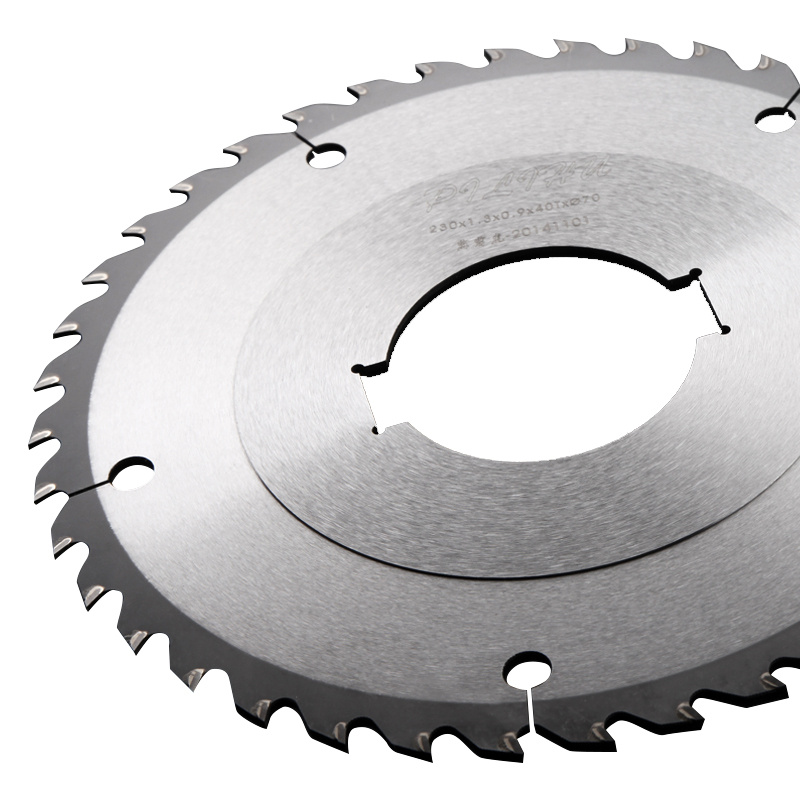

Durable Metal Cut Off Blade for Precision Cutting

By:Admin

The company behind Metal Cut Off Blade, [Company Name], is a leading manufacturer of cutting tools and equipment for the metalworking industry. With over [X] years of experience, [Company Name] has built a solid reputation for delivering high-quality products that meet the demands of modern manufacturing and fabrication processes.

The Metal Cut Off Blade is engineered to deliver exceptional cutting performance and longevity. It is constructed with high-grade materials and incorporates advanced cutting edge technology to ensure superior results. The blade is designed to minimize heat build-up during cutting, reducing the risk of material distortion and improving overall cutting efficiency.

In addition to its exceptional performance, Metal Cut Off Blade is also designed with user safety in mind. The blade features enhanced safety features to protect operators during operation, making it an ideal choice for industrial environments where safety is a top priority.

One of the key advantages of Metal Cut Off Blade is its versatility. It is suitable for a wide range of metal cutting applications, including but not limited to metal fabrication, structural steel cutting, and metalworking. The blade's flexibility makes it a valuable asset for manufacturers and fabricators looking for a reliable cutting solution for various metal materials and thicknesses.

[Company Name] takes pride in its commitment to innovation and continuous improvement. The Metal Cut Off Blade is a result of extensive research and development efforts, aimed at providing customers with cutting-edge solutions that meet the evolving needs of the metalworking industry. The company's dedication to pushing the boundaries of cutting tool technology has positioned it as a leader in the market.

Customers who choose Metal Cut Off Blade can expect exceptional technical support and customer service from [Company Name]. The company's team of skilled professionals is readily available to provide guidance and assistance, ensuring that customers get the most out of their cutting tools. This level of support reflects [Company Name]'s dedication to the success of its customers and its commitment to building long-lasting relationships based on trust and mutual benefit.

As the metalworking industry continues to evolve, [Company Name] remains at the forefront of innovation, driving the development of cutting-edge solutions that empower manufacturers and fabricators to achieve their production goals with precision and efficiency. The Metal Cut Off Blade is a testament to the company's commitment to excellence and its ability to deliver high-performance cutting tools that make a difference in the day-to-day operations of its customers.

In conclusion, Metal Cut Off Blade is a cutting-edge solution for metalworking professionals looking for high performance and precision cutting. Backed by the expertise of [Company Name], this cutting tool offers exceptional cutting performance, versatility, and user safety, making it an invaluable asset for a wide range of metal cutting applications. With a focus on innovation and customer success, [Company Name] continues to lead the way in delivering cutting-edge solutions that meet the evolving needs of the metalworking industry.

Company News & Blog

Ultimate Guide to Choosing the Best Hole Saw for Marble

Marble Hole Saw: A Game-Changer in the Construction IndustryThe construction industry has seen significant advancements in technology over the years, and one such innovation that has revolutionized the way marble is cut is the Marble Hole Saw. This state-of-the-art tool has become an essential part of the construction process, enabling professionals to cut through marble with precision and efficiency.{Company Name}, the leading manufacturer of construction tools and equipment, has been at the forefront of introducing innovative solutions to the industry. With its expertise in developing high-quality tools, the company has successfully designed and produced the Marble Hole Saw, which has garnered widespread acclaim for its cutting-edge features and performance.The Marble Hole Saw is specifically designed to cut through marble, making it an essential tool for professionals working in the construction and renovation industry. Its diamond-tipped cutting edge ensures that the marble is cut with precision and without any chipping or damage. This level of precision is crucial, especially when working with high-end marble surfaces that require a seamless finish.One of the key features of the Marble Hole Saw is its versatility. It can be used with a variety of materials, including ceramic, porcelain, and glass, making it a valuable tool for a wide range of applications. This flexibility has made it a popular choice among contractors and construction professionals who require a reliable and efficient tool for cutting through different materials.In addition to its cutting capabilities, the Marble Hole Saw is also designed for durability and longevity. The use of high-quality materials and the company's advanced manufacturing processes ensure that the tool can withstand the rigors of regular use on construction sites. This reliability is essential for professionals who rely on their tools to deliver consistent performance in demanding environments.Furthermore, {Company Name} has ensured that the Marble Hole Saw is easy to use, with a user-friendly design that simplifies the cutting process. This user-centric approach is a key aspect of the company's commitment to providing practical and efficient solutions to its customers. The tool's ergonomic design and intuitive controls make it accessible to professionals of all skill levels, further contributing to its widespread adoption in the industry.The introduction of the Marble Hole Saw has significantly improved the efficiency and accuracy of cutting marble, eliminating the need for traditional methods that are time-consuming and often result in imperfect cuts. As a result, construction projects can be completed more quickly and with higher levels of precision, ultimately leading to a more satisfactory end result for both professionals and their clients.In conclusion, the Marble Hole Saw has emerged as a game-changer in the construction industry, offering professionals a reliable and efficient tool for cutting through marble and other materials with precision and ease. {Company Name} has once again demonstrated its commitment to innovation and quality, delivering a solution that has had a significant impact on the way marble is handled in construction projects. With its cutting-edge features and exceptional performance, the Marble Hole Saw has undoubtedly become an indispensable tool for professionals in the industry, paving the way for more efficient and successful construction projects.

High-Quality Cutting Blades for Precision Cuts and Efficiency

Cutting Blades Company is a leading manufacturer of high-quality cutting blades for a wide range of industries. The company has been in the business for over 20 years, providing top-of-the-line cutting solutions to its clients. With a strong focus on innovation and product development, Cutting Blades Company has established itself as a trusted partner for businesses seeking reliable and efficient cutting solutions.The company's cutting blades are made from the highest quality materials and are designed to deliver exceptional performance and durability. Whether it's for industrial, manufacturing, or commercial use, Cutting Blades Company offers a comprehensive range of cutting solutions to meet the diverse needs of its customers. From standard blades to custom-made solutions, the company has the expertise and capabilities to deliver cutting-edge products that exceed expectations.One of the key differentiators of Cutting Blades Company is its commitment to continuous improvement and innovation. The company invests heavily in research and development to stay ahead of the curve and provide its customers with cutting-edge solutions that help improve productivity and efficiency. With a dedicated team of engineers and technicians, Cutting Blades Company is constantly pushing the boundaries of what is possible in the world of cutting technology.In addition to its focus on product development, Cutting Blades Company also places a strong emphasis on customer service. The company works closely with its clients to understand their specific cutting needs and provides tailored solutions to meet their requirements. Whether it's a standard blade or a custom-designed product, Cutting Blades Company is dedicated to delivering excellence in every aspect of its business.Furthermore, Cutting Blades Company is committed to sustainability and environmental responsibility. The company adheres to the highest standards of environmental protection and ensures that its manufacturing processes are as eco-friendly as possible. By using cutting-edge technologies and sustainable practices, Cutting Blades Company minimizes its environmental impact while delivering high-quality products to its customers.In recent news, Cutting Blades Company has announced the launch of its latest line of cutting blades, designed to enhance cutting performance and efficiency for its customers. The new blades are the result of extensive research and development efforts, aimed at delivering superior cutting solutions that meet the evolving needs of the industry."We are excited to introduce our new line of cutting blades, which represent the latest advancements in cutting technology," said the spokesperson for Cutting Blades Company. "These blades have been meticulously designed and tested to deliver exceptional cutting performance, durability, and precision. We are confident that they will set a new standard for cutting solutions in the industry."The new line of cutting blades offers a range of features and benefits, including improved cutting speed, enhanced precision, and extended blade life. Whether it's for wood, metal, plastic, or other materials, the new blades are engineered to deliver superior performance across a wide range of applications. With its latest product launch, Cutting Blades Company continues to demonstrate its commitment to innovation and excellence in the cutting industry.As Cutting Blades Company continues to grow and expand its presence in the market, the company remains dedicated to its core values of quality, innovation, and customer satisfaction. With its relentless focus on delivering cutting-edge solutions and unparalleled customer service, Cutting Blades Company is well-positioned to remain a leader in the cutting industry for years to come.In conclusion, Cutting Blades Company is a trusted manufacturer of high-quality cutting blades, offering innovative solutions for a wide range of industries. With its commitment to excellence, sustainability, and customer satisfaction, Cutting Blades Company continues to set new standards in the cutting industry and remains a top choice for businesses seeking reliable and efficient cutting solutions.

: "Durable and Precise Jigsaw Blades for Your Next DIY Project

[Company Name] Introduces Next Generation Jig Saw Blades for Increased Precision and Efficiency[City, State] - The leading manufacturer of cutting-edge power tools and accessories, [Company Name], is excited to announce the release of their latest innovation: the next generation jig saw blades. Designed for professional tradesmen and DIY enthusiasts alike, these new blades are engineered to provide superior cutting performance, durability, and precision.With a long-standing commitment to quality and innovation, [Company Name] has been a trusted name in the power tool industry for over [X] years. Their dedication to producing reliable and high-performance products has earned them a loyal customer base and a reputation for excellence. The introduction of the next generation jig saw blades further solidifies their position as a driving force in the industry."We are thrilled to unveil our latest breakthrough in cutting technology with the release of our next generation jig saw blades," said [Spokesperson Name], [Title] at [Company Name]. "We understand the importance of having the right tools for the job, which is why we have invested significant time and resources into developing blades that are not only durable and long-lasting but also deliver precise and efficient cuts."The new jig saw blades boast several innovative features that set them apart from the competition. Constructed from premium materials, the blades are engineered to withstand the rigors of heavy-duty cutting applications, making them ideal for demanding job sites and professional use. Additionally, the blades are designed to minimize deflection and vibration during operation, resulting in cleaner and more accurate cuts.One of the key highlights of the next generation jig saw blades is their optimized tooth design, which enables faster cutting speeds and improved chip evacuation for enhanced efficiency. This feature is especially beneficial for tradesmen who need to complete jobs quickly and accurately without compromising on quality. Furthermore, the blades are compatible with a wide range of jig saws, providing versatility and convenience for users.Incorporating customer feedback and industry trends into the product development process, [Company Name] has ensured that the new jig saw blades address the evolving needs of professionals and hobbyists. Whether it's cutting through wood, metal, plastic, or other materials, users can rely on the blades to deliver consistent and reliable performance, resulting in a smoother cutting experience and professional-quality results.To further showcase the capabilities of the next generation jig saw blades, [Company Name] has conducted rigorous testing and quality assurance measures to validate their performance and durability. The blades have surpassed industry standards and have been proven to outlast and outperform competing products in head-to-head comparisons."We take pride in delivering best-in-class solutions that empower our customers to achieve their goals with confidence," added [Spokesperson Name]. "The introduction of our next generation jig saw blades is a testament to our ongoing commitment to innovation and excellence."In addition to the release of the new jig saw blades, [Company Name] continues to expand its product lineup with a focus on providing comprehensive solutions for cutting, drilling, and fastening needs. With an extensive distribution network and a dedication to customer satisfaction, the company remains at the forefront of the power tool and accessories market.The next generation jig saw blades are now available for purchase through authorized [Company Name] retailers and online distributors. For more information about the new blades and other products offered by [Company Name], visit their official website or contact their customer support team. With a legacy of innovation and a forward-thinking approach, [Company Name] is poised to continue setting new benchmarks in the industry.

Best Concrete Cutting Wheel for Grinder: A Complete Guide

Concrete Cutting Wheel For Grinder is a new product recently introduced by a leading company in the construction industry. This cutting wheel is designed to be used with a grinder, making it easier and more efficient to cut through concrete, stone, and other tough materials on construction sites. The company has a long history of providing high-quality products and innovative solutions for construction professionals, and the Concrete Cutting Wheel For Grinder is no exception.One of the key features of the Concrete Cutting Wheel For Grinder is its durability. Made from high-quality materials, this cutting wheel is designed to withstand the tough conditions of construction sites. Whether it's cutting through thick concrete or tackling other challenging materials, this cutting wheel is built to last. This durability is essential for construction professionals who rely on their tools to withstand the rigors of their work.In addition to its durability, the Concrete Cutting Wheel For Grinder is also designed for precision and accuracy. The company has taken great care to ensure that this cutting wheel provides clean and precise cuts, allowing construction professionals to get the job done with the utmost precision. This level of accuracy is essential for ensuring that construction projects are completed to the highest standards.Another important feature of the Concrete Cutting Wheel For Grinder is its versatility. This cutting wheel is suitable for a wide range of applications, making it a valuable tool for construction professionals. Whether it's cutting through concrete, stone, or other tough materials, this cutting wheel is designed to handle the job with ease. This versatility makes it an ideal choice for construction professionals who need a reliable and efficient cutting tool for a variety of tasks.The company behind the Concrete Cutting Wheel For Grinder has a strong reputation for delivering high-quality products and exceptional service to its customers. With a focus on innovation and excellence, this company has become a trusted name in the construction industry. Their commitment to providing cutting-edge solutions to construction professionals is evident in the quality and performance of the Concrete Cutting Wheel For Grinder.In addition to its focus on product quality, the company also places a high value on customer satisfaction. They understand the unique needs of construction professionals and strive to provide products that meet and exceed those needs. The Concrete Cutting Wheel For Grinder is just one example of how this company is dedicated to delivering reliable and effective solutions to its customers.The introduction of the Concrete Cutting Wheel For Grinder is a reflection of the company's ongoing commitment to innovation and excellence. By providing construction professionals with a durable, precise, and versatile cutting tool, this company is helping to improve efficiency and productivity on construction sites. With its strong reputation for quality and customer satisfaction, the company is well-positioned to continue leading the way in the construction industry.In conclusion, the introduction of the Concrete Cutting Wheel For Grinder by this leading company in the construction industry is a significant development for construction professionals. With its focus on durability, precision, and versatility, this cutting wheel is poised to become an essential tool for a wide range of construction applications. With a strong reputation for quality and customer satisfaction, this company is well-equipped to meet the needs of construction professionals and continue driving innovation in the construction industry.

High-performance Oscillating Blade for Cutting Carbide

Carbide Oscillating Blade has revolutionized the cutting industry with its high-quality, durable blades that provide unmatched precision and efficiency. The company has been a leader in the blade manufacturing industry for over 20 years, and their commitment to innovation and customer satisfaction has set them apart from the competition.The Carbide Oscillating Blade is a game-changer in the cutting industry, with its unique design and superior performance. It is made with high-quality carbide, a material known for its extreme hardness and durability. This allows the blade to stay sharp for longer periods of time, reducing the need for frequent blade changes and ultimately saving time and money for the user.The oscillating action of the blade ensures a smooth and precise cut, making it the ideal choice for a wide range of cutting applications. Whether it’s for woodworking, metal fabrication, or general construction, the Carbide Oscillating Blade can handle it all with ease.One of the key features that set the Carbide Oscillating Blade apart from its competitors is its versatility. It is compatible with a wide range of oscillating tools, making it a convenient choice for professionals and DIY enthusiasts alike. With the ability to tackle various materials and cutting tasks, the Carbide Oscillating Blade is a must-have tool for any workshop or job site.In addition to its superior performance, the Carbide Oscillating Blade is also designed with user safety in mind. The blade is engineered to reduce kickback and vibration, providing a smooth and controlled cutting experience. This attention to safety ensures that users can operate the blade with confidence and peace of mind.With a strong commitment to customer satisfaction, Carbide Oscillating Blade offers top-notch customer service and support. Their team of experts is dedicated to helping customers find the right blade for their specific needs and providing ongoing support and assistance. This level of care and support further solidifies Carbide Oscillating Blade's position as an industry leader.The company's dedication to quality and innovation doesn't stop at their products. They also prioritize sustainable and eco-friendly manufacturing practices, ensuring that their blades are not only high-performing but also environmentally responsible.As the demand for high-quality cutting tools continues to grow, Carbide Oscillating Blade remains dedicated to meeting the needs of its customers. With a strong focus on quality, performance, and customer satisfaction, they are poised to remain a leader in the blade manufacturing industry for years to come.In conclusion, Carbide Oscillating Blade has proven to be a game-changer in the cutting industry, offering high-quality, durable blades that deliver unmatched precision and efficiency. With a strong commitment to innovation, customer satisfaction, and sustainability, the company has solidified its position as an industry leader. Whether it's for professional or DIY use, the Carbide Oscillating Blade is the go-to choice for anyone looking for a reliable and versatile cutting tool.

Discover the Ultimate Saw Blade for Efficient Cutting - A Complete Guide

Title: Industry-Leading Rod Saw Blade Revolutionizes Cutting Efficiency and PrecisionIntroduction:[Company Name], a prominent industry player known for its cutting-edge tools and machinery, has recently unveiled its latest innovation in the field of cutting technology – the state-of-the-art Rod Saw Blade. Developed after years of research and development, this cutting-edge tool is set to transform the way professionals carry out their cutting tasks, enhancing both efficiency and precision.With an unwavering commitment to innovation, [Company Name] has established itself as a trusted name in the industry. Their exceptional track record of producing high-performance tools reflects their dedication to meeting the evolving needs of professionals in various trades, from construction to woodworking, metalwork, and beyond.The Rod Saw Blade:The Rod Saw Blade is the newest gem in [Company Name]'s extensive portfolio of cutting tools. Designed to excel in demanding applications, this blade offers unparalleled performance, setting a new industry standard.To ensure exceptional performance and longevity, the blade is meticulously crafted using premium-grade materials. Combine this with advanced manufacturing techniques, and professionals can rely on Rod Saw Blade to withstand the most rigorous cutting tasks.Key features and benefits of the Rod Saw Blade include:1. Superior Cutting Performance: The Rod Saw Blade boasts sharp, ultra-hard teeth that enable effortless cutting through even the toughest materials. From dense plywood to solid steel rods, this blade delivers precise cuts with ease, reducing the time and effort required for each task.2. Enhanced Durability: With its durable construction, the Rod Saw Blade retains its cutting edge for an extended period, ensuring consistent performance throughout its lifespan. This significantly reduces downtime and lowers overall operational costs.3. Versatility: Designed to cater to a diverse range of applications, the Rod Saw Blade effortlessly tackles various materials, including wood, plastic, metal, and more. Its adaptability makes it an indispensable tool for professionals across different industries.4. Safety and Ergonomics: [Company Name] prioritizes user safety, and the Rod Saw Blade reflects this commitment. The blade features an ergonomic design, reducing strain on the user's hand, thus preventing potential injuries and enhancing overall comfort.Industry Impact:The introduction of the Rod Saw Blade marks a significant milestone for [Company Name] and has elicited considerable excitement within the industry. With its advanced features and exceptional performance, professionals across sectors can expect a substantial boost in their productivity levels.Construction professionals can now complete intricate tasks, such as cutting through concrete or installing plumbing pipes, with increased precision and speed. Similarly, woodworkers will benefit from the blade's ability to effortlessly handle various types of wood, irrespective of density or thickness.Moreover, metalworkers and individuals working in fabrication will appreciate the Rod Saw Blade's versatility in handling different metals, including steel rods, aluminum sheets, and copper pipes. This tool empowers them to undertake complex projects with ease, meeting tight deadlines without compromising quality.Conclusion:[Company Name]'s introduction of the Rod Saw Blade signals a groundbreaking advance in cutting technology. With its exceptional performance, durability, versatility, and commitment to user safety, this innovation promises to revolutionize cutting efficiency and precision, empowering professionals across various industries.As [Company Name] continues to push the boundaries of tool innovation, it solidifies its position as an industry leader, delivering unparalleled solutions that exceed expectations. The Rod Saw Blade is just one example of their unwavering dedication to equipping professionals with state-of-the-art tools to enhance their productivity and ultimately achieve outstanding results.

Discover the Latest Innovations in Grinding Wheels

Title: Innovations in the Grinding Industry: The Rise of CBN Grinding WheelsIntroduction:In the ever-evolving world of industrial manufacturing, companies are constantly seeking new solutions to increase efficiency and productivity. One such innovation that has transformed the grinding industry is Cubic Boron Nitride (CBN) grinding wheels. These cutting-edge tools have made significant strides in overcoming the limitations of traditional grinding wheels, enabling companies to achieve superior grinding performance and precision.CBN Grinding Wheels: A Game-Changer in Precision GrindingCBN grinding wheels are made from Cubic Boron Nitride, a synthetic crystalline material that is second only to diamonds in hardness. This exceptional hardness, combined with CBN's superior thermal and chemical stability, allows these wheels to endure high grinding temperatures and demanding conditions without losing their effectiveness or shape.Unlike conventional grinding wheels, which are predominantly made of aluminum oxide or silicon carbide, CBN wheels offer distinct advantages that revolutionize precision grinding processes across industries. CBN wheels not only provide increased grinding efficiency but also facilitate exceptional surface finish, reduced cycle times, and improved overall productivity.Applications in Various Industries:1. Automotive Industry:Automakers and component manufacturers have recognized the potential of CBN grinding wheels in enhancing production processes. CBN wheels are widely used for precise grinding of hardened steel, cast iron, and other difficult-to-machine materials, enabling manufacturers to achieve tight tolerances required for automotive parts like engine components, transmission parts, and camshafts. The exceptional durability of CBN wheels ensures they maintain their form and sharpness, resulting in consistent and reliable performance.2. Aerospace Industry:With their ability to grind super alloys and other heat-resistant materials like titanium and nickel alloys, CBN wheels have garnered significant attention in the aerospace sector. The aerospace industry demands components with extremely tight tolerances, and CBN wheels enable manufacturers to achieve these high-precision results efficiently. From turbine blades to landing gear components, CBN grinding wheels have become an indispensable tool for producing critical aerospace parts.3. Medical Industry:In the medical industry, CBN grinding wheels have proven instrumental in the production of medical devices and surgical instruments. With their ability to grind materials like stainless steel, titanium, and ceramics, CBN wheels ensure precision and surface finish, crucial for medical applications. The medical industry benefits from increased productivity and uniformity in the manufacturing process, allowing for consistent quality control and minimized downtime.Future Trends and Technological Advancements:With the growing demand for precision grinding, manufacturers are investing in research and development to further enhance CBN grinding wheel technology. Several key advancements are being explored, such as developing hybrid grinding wheels that combine the benefits of CBN and diamond abrasive materials, enabling even greater versatility and efficiency in grinding processes.Moreover, advancements in bonding technologies are increasing the wheel's resilience and integrity, resulting in extended tool life and reduced maintenance costs. The use of advanced manufacturing techniques, including advanced laser techniques for wheel shaping and profiling, is also being implemented to improve wheel performance and enhance overall efficiency.Conclusion:CBN grinding wheels have emerged as a game-changer in the grinding industry, providing manufacturers with a tool that offers superior performance, extended tool life, and unmatched precision. These wheels have found applications across diverse industries, including automotive, aerospace, and medical, revolutionizing their respective grinding processes.As advancements continue to propel the development of CBN grinding wheels, manufacturers will undoubtedly witness even greater improvements in grinding efficiency, accuracy, and productivity. With these cutting-edge tools at their disposal, companies can optimize their manufacturing processes, resulting in cost savings, improved quality, and increased competitiveness in the global market.

Best Masonry Hole Saw for Professional Use

Introducing the Latest Innovation in Masonry Hole Saw Technology[Company Name], a renowned leader in the tool industry, has recently announced the launch of their newest product – the Masonry Hole Saw. This innovative tool is designed to revolutionize the way professionals and DIY enthusiasts approach masonry projects, offering precision, efficiency, and durability like never before.The [Company Name] Masonry Hole Saw is engineered with advanced technology and high-quality materials, making it the ideal choice for cutting clean and precise holes in a variety of masonry materials such as brick, concrete, and stone. With its cutting-edge design, this tool ensures minimal chipping and a smooth finish, saving both time and effort for the user.One of the key features of the [Company Name] Masonry Hole Saw is its diamond-coated cutting edge, which provides superior cutting performance and extended durability. This innovative design allows for efficient and precise hole cutting, while ensuring a longer lifespan compared to traditional hole saws.Another notable aspect of this product is its compatibility with a wide range of power tools, including corded and cordless drills, making it a versatile and convenient choice for professionals and DIYers alike. Additionally, the [Company Name] Masonry Hole Saw is available in various sizes to accommodate different project requirements, further solidifying its position as a go-to tool for masonry work.In addition to its exceptional performance, the [Company Name] Masonry Hole Saw is also designed with user safety and comfort in mind. The tool features a specially engineered pilot bit that ensures stability during operation, reducing the risk of kickback and enhancing overall control. Furthermore, its ergonomic design and lightweight construction make it easy to handle, minimizing user fatigue during extended use.As a forward-thinking company, [Company Name] is dedicated to providing innovative solutions that meet the evolving needs of professionals and enthusiasts in the construction and DIY sectors. The launch of the Masonry Hole Saw is a testament to this commitment, as it represents a significant advancement in masonry cutting technology that promises to enhance efficiency and precision in a wide range of applications.With the introduction of the [Company Name] Masonry Hole Saw, the company continues to uphold its reputation for delivering high-quality, reliable, and innovative tools that empower users to achieve outstanding results. As a highly respected brand in the industry, [Company Name] remains at the forefront of tool innovation, consistently setting new standards for performance and functionality.The [Company Name] Masonry Hole Saw is now available for purchase, offering professionals and DIY enthusiasts the opportunity to experience the next level of masonry hole cutting. With its advanced features, exceptional durability, and user-friendly design, this tool is set to become an indispensable asset for anyone working with masonry materials.In conclusion, the launch of the [Company Name] Masonry Hole Saw represents a significant milestone in the tool industry, showcasing the company's dedication to innovation and excellence. With its cutting-edge technology and superior performance, this tool is poised to make a lasting impact on the way masonry projects are approached, setting a new standard for precision, efficiency, and durability. For professionals and DIYers seeking the best in masonry hole cutting, the [Company Name] Masonry Hole Saw is undoubtedly a game-changing solution that will elevate their work to new heights.

Durable and Efficient Grinding Wheel for Ag7 Machinery

Ag7 Grinding Wheel, a product of a leading manufacturer of abrasives and grinding solutions, is making waves in the industrial market with its high performance and efficiency. With a focus on innovation and quality, the company has established a strong presence in the grinding industry, redefining standards and setting new benchmarks.The Ag7 Grinding Wheel is designed to meet the demands of modern industrial applications, offering exceptional results in terms of material removal and surface finish. Its superior performance can be attributed to the use of advanced abrasive materials and state-of-the-art manufacturing processes, ensuring consistency and reliability in every grind. Whether it's for heavy-duty metal grinding or precision surface finishing, this product delivers optimal results, making it the preferred choice for professionals and industries alike.The company behind Ag7 Grinding Wheel has a rich legacy of expertise and experience in the field of abrasives and grinding solutions. With a strong focus on research and development, they continue to push the boundaries of innovation, introducing cutting-edge technologies and materials that enhance the performance and efficiency of their products. Their commitment to quality is evident in the rigorous testing and quality control measures employed at every stage of production, ensuring that each Ag7 Grinding Wheel meets the highest standards of excellence.In addition to its exceptional performance, the Ag7 Grinding Wheel is also known for its durability and longevity, making it a cost-effective solution for industrial grinding operations. Its ability to maintain consistent performance over extended periods of use minimizes downtime and maintenance costs, providing businesses with a competitive edge and enhanced productivity. Furthermore, the company's unwavering commitment to sustainability and environmental responsibility ensures that their products are manufactured using eco-friendly processes and materials, aligning with the global shift towards green and sustainable practices.The Ag7 Grinding Wheel is available in a variety of specifications and configurations to cater to diverse grinding requirements, catering to the specific needs of different industries and applications. Whether it's for heavy stock removal, surface blending, or edge chamfering, there is a suitable Ag7 Grinding Wheel that ensures optimal performance and results. Furthermore, the company offers comprehensive technical support and customer service, ensuring that clients receive the guidance and assistance they need to maximize the potential of their grinding operations.Looking ahead, the company remains committed to advancing the field of abrasives and grinding solutions, promising further innovation and breakthroughs that will continue to raise the bar for performance and efficiency. With a dedication to excellence and a passion for pushing boundaries, Ag7 Grinding Wheel is set to remain a trusted and preferred choice for industrial grinding needs, setting new standards and delivering superior results. As industries continue to evolve and demand higher levels of precision and productivity, the Ag7 Grinding Wheel is poised to play a pivotal role in shaping the future of grinding technology.In conclusion, Ag7 Grinding Wheel, backed by a leading manufacturer of abrasives and grinding solutions, offers a compelling combination of performance, reliability, and sustainability. With a strong focus on innovation and quality, the company has established itself as a prominent player in the industry, providing cutting-edge solutions that redefine the standards of industrial grinding. As businesses and industries continue to seek superior grinding solutions, the Ag7 Grinding Wheel stands out as a top choice, delivering optimal performance, durability, and cost-effectiveness. As the company continues to drive innovation and excellence, the future looks bright for Ag7 Grinding Wheel and its role in shaping the landscape of industrial grinding.