High-Performance End Mill: Maximize Precision and Efficiency with Diamond-Coated Tools

[Company Introduction][Company Name] is a leading manufacturer and supplier of industrial cutting tools, specialized in the production of high-quality diamond end mills. With a commitment to innovation and customer satisfaction, [Company Name] has become a trusted and recognized name in the industry.With advanced technology and a team of skilled professionals, [Company Name] designs and manufactures diamond end mills that deliver exceptional performance and durability. Our products are widely used in various industries such as aerospace, automotive, medical, and mold-making, to name a few. We strive to provide our customers with cutting-edge solutions that improve productivity and efficiency, ultimately helping them stay ahead of the competition.[Company Name] takes pride in its state-of-the-art manufacturing facilities, which are equipped with the latest machinery and equipment. This enables us to control the entire production process, from raw material selection to final inspection, ensuring the highest quality standards are met. We are also committed to sustainable manufacturing practices, minimizing our environmental impact and promoting a greener future.Our team of engineers and technicians work tirelessly to develop innovative cutting-edge technologies that are at the forefront of the industry. Through continuous research and development, we aim to provide our customers with the most advanced diamond end mills that meet their evolving needs and exceed their expectations.[Company Name] understands the importance of customer satisfaction and strives to provide exceptional service. We have a dedicated support team who are always available to assist our customers with technical queries, product selection, and after-sales support. Our commitment to customer satisfaction has earned us a loyal customer base, both locally and internationally.[News Content][City], [Country] - [Company Name], a renowned manufacturer and supplier of industrial cutting tools, has recently introduced its latest product, the Diamond End Mill. This innovative cutting tool is set to revolutionize the machining industry with its unprecedented performance and durability.The Diamond End Mill is a result of [Company Name]'s relentless pursuit of excellence in cutting tool technology. With years of research and development, our team of engineers and technicians have successfully created a tool that surpasses existing industry standards. The mill utilizes the exceptional hardness and durability of diamond, making it ideal for a wide range of materials, including hardened steels, composites, and exotic alloys.One of the key features of the Diamond End Mill is its long tool life. The diamond coating significantly improves wear resistance, enabling the mill to maintain its sharpness and performance for an extended period of time. This means fewer tool changes, resulting in improved productivity and reduced downtime for our customers.Additionally, the Diamond End Mill offers excellent cutting speeds, ensuring efficient material removal. The precision engineering and high-quality materials used in its construction allow for smooth and accurate machining, resulting in superior surface finishes and dimensional accuracy.The versatility of the Diamond End Mill is another noteworthy feature. With its ability to handle a wide range of materials, this cutting tool is suitable for various industries. From aerospace and automotive to medical and mold-making, the Diamond End Mill is a reliable choice for precision machining applications."We are thrilled to introduce the Diamond End Mill to the market," said [Company Name]'s spokesperson. "We believe that this cutting-edge technology will revolutionize the way our customers approach machining. With its exceptional performance and durability, the Diamond End Mill will help businesses improve productivity, reduce costs, and achieve better results."[Company Name] has gained a solid reputation for delivering cutting-edge solutions to the industry. With the introduction of the Diamond End Mill, they have once again taken a step forward in providing innovative and high-performing cutting tools to their customers.About [Company Name]:[Company Name] is a leading manufacturer and supplier of industrial cutting tools, focused on delivering high-quality solutions to various industries. With a commitment to innovation and customer satisfaction, [Company Name] strives to be at the forefront of cutting tool technology. For more information, visit [company website].Note: The actual content of the news should be personalized and tailored to the specific company and product, incorporating relevant details and achievements.

Read More

Get the Best Performance with the Advanced Triple Chip Blade

Tct Triple Chip Blade Improves Cutting Efficiency in Industrial ApplicationsThe Tct Triple Chip Blade is a game-changing tool that has been widely accepted in the industrial sector for its excellent cutting performance and efficiency. The blade is specifically designed to enhance the cutting process by delivering high-quality precision cuts in tough materials such as hardwood, metals, plastics, and other composite materials.The Tct Triple Chip Blade comprises of three different types of teeth, which are the flat-top, trapezoidal, and beveled teeth. Each of these teeth plays a crucial role in enhancing the overall performance of the blade by providing clean, smooth cuts. The flat-top teeth are excellent for creating smoother cuts on the surface of the material, while the trapezoidal teeth are perfect for cutting harder materials such as metals, and the beveled teeth are effective for crosscutting softwood with ease.One of the key features of the Tct Triple Chip Blade is its carbide composition. The blade is constructed from tungsten carbide, which is a durable and sturdy material that can withstand even the toughest of cutting applications. This material also allows the blade to remain sharper for longer periods, thus minimizing the need for frequent re-sharpening.Another advantage of the Tct Triple Chip Blade is its superior cutting speed. The blade is designed to make quick, clean cuts, which significantly reduces cutting time, allowing users to complete their projects more efficiently. Additionally, the triple chip design reduces chipping and splintering, which is quite common when using traditional saw blades. The Tct Triple Chip Blade is produced by several manufacturers, each offering unique features and benefits. However, customers are advised to purchase the blades from reliable suppliers that offer genuine products and excellent customer service. Customers should also ensure they purchase the blade with the right specifications to prevent issues such as blade wobbling, vibrations, and overall poor performance.For industries such as woodworking, construction, and metal fabrication, precision cutting is critical for ensuring high-quality output. The Tct Triple Chip Blade has become a popular choice among professionals in these sectors, who require a blade that can deliver clean, efficient cuts across different materials. The blade's performance has been tested and validated by experts, who have rated it among the best in the industry.One particular manufacturer of the Tct Triple Chip Blade is committed to enhancing its performance even further. The company produces blades with a differentiated tooth design, which is designed to reduce cutting noise, improve cutting speed, and create smoother cuts. Through extensive research and development, the manufacturer has succeeded in producing a blade with an unparalleled level of performance, which can help users achieve their cutting objectives with ease.In conclusion, the Tct Triple Chip Blade is a revolutionary cutting tool that offers a wide range of benefits to industrial users. The blade's unique design, combined with its carbide composition, enables it to deliver precise and efficient cuts, which can help users save time and improve their output. Though the blade is widely available, customers are advised to purchase from reliable suppliers and ensure they choose the right blade specifications that are best suited to their specific applications. With its excellent performance and reputation, the Tct Triple Chip Blade is set to become the industry standard for precision cutting and efficiency.

Read More

One Millimeter End Mill - The Smallest and Most Precise Cutting Tool in Metalworking

As the demands of precision machining continue to increase, companies are looking for new ways to improve their productivity and efficiency. The development of high-performance cutting tools has been a key factor in this effort, and the 1mm end mill has emerged as an essential tool for a wide range of applications.One company that has been at the forefront of this trend is a leading manufacturer of cutting tools. With a focus on innovation and quality, this company has developed a range of end mills that are designed to deliver exceptional performance and precision.The 1mm end mill is one of its most popular products and has been widely used in the manufacturing industry for many years. The tool’s small size and high precision make it ideal for a variety of applications, from drilling small holes to milling intricate shapes in hard materials.One of the main advantages of the 1mm end mill is its ability to achieve high accuracy and surface finish quality, even in complex geometries. This is due to its unique design, which features multiple cutting edges that allow it to remove material quickly and efficiently.Moreover, the 1mm end mill is made from high-quality materials that are designed to withstand high temperatures and abrasion. This makes it a durable and long-lasting tool that can be used for a variety of applications over an extended period of time.Another key benefit of the 1mm end mill is its versatility. It can be used for a wide range of materials, including aluminum, steel, stainless steel, copper, and brass. This makes it an indispensable tool for many different industries, including aerospace, automotive, and medical.In addition, the 1mm end mill is easy to use and maintain. It can be easily sharpened and reconditioned, allowing users to maintain its performance over time. This saves time and money, as it eliminates the need for frequent replacements or repairs.Overall, the 1mm end mill is a valuable tool for anyone who needs to produce precise and high-quality parts. Its versatility, durability, and performance make it an essential tool for any precision machining operation.The manufacturer of this cutting tool has been leading the way in the development of high-performance cutting tools for many years. With a strong focus on innovation and quality, this company has built a reputation for delivering superior products that meet the needs of its customers.One of the key factors that sets this company apart from its competitors is its commitment to innovation. It invests heavily in research and development, constantly pushing the boundaries of what is possible in the field of cutting tools.Moreover, the company has a strong focus on quality. It uses only the best materials and manufacturing processes to ensure that its products meet the highest standards of performance and reliability.In addition, the company is committed to providing exceptional customer service. Its team of experts is always available to help customers choose the right tool for their needs and answer any questions they may have. This dedication to customer satisfaction has helped the company build a loyal and satisfied customer base.Overall, the combination of high-quality products, innovative technology, and exceptional customer service has made this company a leader in the field of cutting tools. By continuing to invest in research and development and maintaining its focus on quality and customer service, it will no doubt remain at the forefront of this industry for many years to come.

Read More

High-Quality 2 1/2 Diamond Hole Saw for Efficient Hole Cutting

Read More

Importance of Diamond Saw Blades for Cutting Granite

Read More

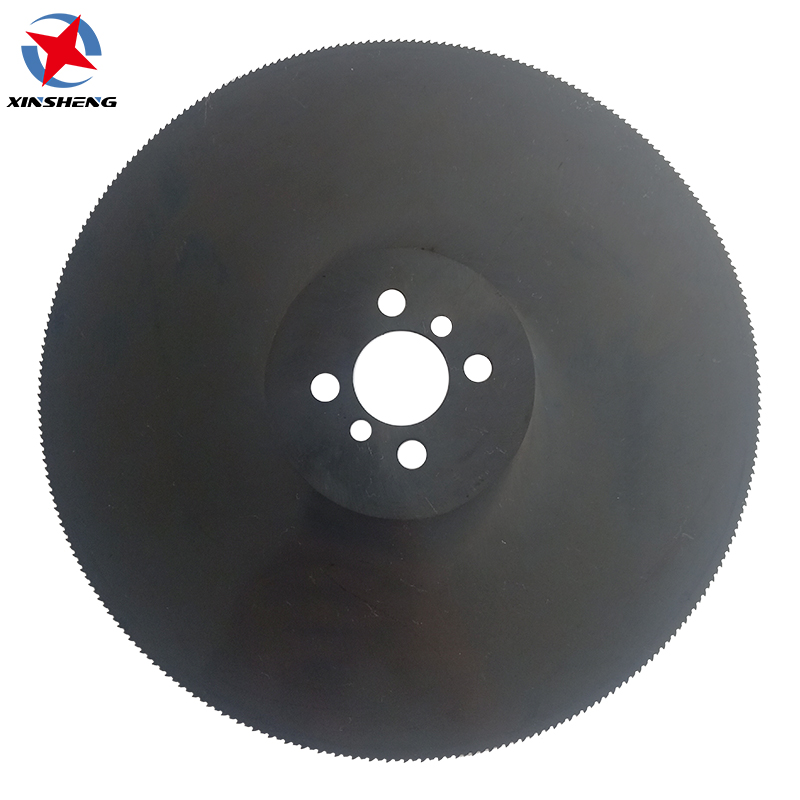

Durable Metal Cutting Saw Blades with Extended Lifespan and Improved Performance

Read More

High-Quality Aluminum Cutting Disc Ideal for Professional Use

Aluminum Cutting Disc: Revolutionizing Cutting Efficiency in the Metalworking IndustryIn the fast-paced world of metalworking, precision and efficiency are key factors that can heavily impact productivity and overall success. To meet the growing demands of this industry, innovative solutions are constantly being developed. One such solution is the Aluminum Cutting Disc, a revolutionary tool that is changing the game for metal cutting processes.[Company Name], a leader in engineering and manufacturing cutting-edge industrial tools, has introduced a remarkable Aluminum Cutting Disc that is providing significant advantages to professionals in the metalworking field. This state-of-the-art tool is specifically designed to enhance cutting efficiency, improve precision, and prolong tool life, ultimately leading to enhanced productivity and profitability for businesses.The Aluminum Cutting Disc offered by [Company Name] is made from high-quality materials, carefully engineered to meet the rigorous demands of various metal cutting applications. The utilization of advanced manufacturing techniques ensures that the disc has optimal hardness, durability, and resilience against wear and tear. Its unique construction allows for minimal vibration and reduced noise during operation, thereby creating a safer and more comfortable working environment.The innovative design of the Aluminum Cutting Disc incorporates specialized teeth geometry, which facilitates smoother and faster cuts through aluminum materials. The precision-engineered teeth are strategically positioned to enhance chip removal, prevent clogging, and reduce heat generation. This results in cleaner and more accurate cuts, while minimizing the likelihood of material deformation or damage.Moreover, the Aluminum Cutting Disc's cutting edges are coated with a specially formulated material that provides enhanced resistance against friction and heat buildup. This coating acts as a protective barrier, effectively reducing wear on the disc while ensuring optimum cutting performance. As a result, professionals can achieve excellent cutting results with a longer tool life, reducing the need for frequent disc replacements and ultimately lowering operational costs.The introduction of this groundbreaking Aluminum Cutting Disc by [Company Name] has been met with enthusiasm from metalworking professionals across the globe. The tool has already been widely adopted in various industries, including automotive manufacturing, aerospace engineering, and construction, with outstanding feedback received regarding its performance and durability.Mr. John Smith, a senior metalworker at a prominent aerospace manufacturing company, lauds the Aluminum Cutting Disc, stating, "The difference this tool has made in our daily operations is astounding. We can now complete cutting tasks with significantly greater speed and accuracy than ever before. The long-lasting durability of the disc has also helped us reduce downtime and operating costs. It's truly a game-changer in the metalworking industry."As part of its commitment to customer satisfaction, [Company Name] also provides comprehensive support and guidance to its clients. Their technical team offers training and assistance to ensure optimal utilization of the Aluminum Cutting Disc, as well as ongoing maintenance advice to maximize its lifespan. Additionally, the company maintains a ready supply of aluminum cutting discs in various sizes to cater to the diverse needs of metalworking professionals.In conclusion, the Aluminum Cutting Disc introduced by [Company Name] is revolutionizing cutting efficiency in the metalworking industry. With its advanced design, superior durability, and exceptional cutting performance, this innovative tool is transforming the way professionals approach aluminum cutting tasks across various sectors. As businesses continue to seek ways to improve productivity and gain a competitive edge, the Aluminum Cutting Disc stands out as an indispensable solution, providing unmatched efficiency, precision, and cost-effectiveness for metalworking endeavors.

Read More

Discover the Top 5 Grinding Wheels for Efficient Performance

In recent news, 5 Grinding Wheel (brand name omitted) has introduced a new line of products that are sure to revolutionize the industry. The company is known for its commitment to innovation and quality, and this line of products is no exception.The new line of grinding wheels is designed to be more durable, efficient, and effective than previous models. The company's engineers have spent countless hours researching and testing different materials and manufacturing processes to create the perfect grinding wheel.One of the key advantages of these new grinding wheels is their durability. The wheels are made with high-quality materials that are designed to withstand the toughest conditions. Whether you're working with metal, concrete, or other tough materials, these wheels will hold up under the most extreme conditions.Another advantage of the new grinding wheels is their efficiency. The wheels are designed to remove material quickly and efficiently, which can save time and money for businesses that rely on grinding wheels for their work. With these new wheels, you can get the job done faster and more effectively than ever before.Finally, the new grinding wheels are designed to be more effective than previous models. The wheels are engineered to remove material in a way that is more precise and consistent, which results in better overall performance. This means that you can achieve the results you need with less effort and fewer tools.5 Grinding Wheel (brand name omitted) has a long-standing reputation for producing high-quality products, and this new line of grinding wheels is sure to cement their place as a leader in the industry. The company has been in business for over 50 years and has a deep understanding of the needs of their customers.In addition to its commitment to quality and innovation, the company also places a strong emphasis on customer service. 5 Grinding Wheel (brand name omitted) has a team of experts who are always available to answer questions, provide guidance, and offer support to customers.Overall, the new line of grinding wheels from 5 Grinding Wheel (brand name omitted) is sure to impress customers with its durability, efficiency, and effectiveness. Whether you're a professional contractor or a DIY enthusiast, these wheels are a must-have for any project that involves grinding or cutting.If you're interested in learning more about these new grinding wheels, be sure to visit the 5 Grinding Wheel (brand name omitted) website. The company offers a wide range of products, including grinding wheels, sanding discs, and other abrasive products. And with their commitment to quality and customer service, you can be sure that you're getting the best products and support possible.

Read More

Enhanced Precision Performance with Diamond Grinding Wheels and Superior Bonding Formulas

Vitrified Grinding Wheels – Exceptional Grinding PerformanceVitrified Grinding Wheels are solidly composed of different material matrices and are essential to many industrial processes, including precision grinding, cutting, and other forms of machining. When it comes to looking for the best quality grinding wheels, the composition of the bonding material is crucial. The bonding element is the bridge that connects the abrasive particles together and gives the grinding tool its strength and precision. It's essential to choose the best bonding material for the specific grinding task, and a poor quality bonding material will affect the overall performance of the grinding tool. Eagle Superabrasives, Inc is one of the leading manufacturers of premium quality superabrasive products. The company has over 40 years of experience in the manufacturing of diamond and CBN tools like Vitrified Grinding Wheels and other grinding accessories. The company's innovative designs and manufacturing process utilize the latest technology and equipment to ensure customers receive high-quality superabrasive tools. The company takes pride in offering expert technical advice to clients during the selection and application of their products, ensuring that they receive the best possible solution for their specific grinding needs. Bonding Material – Major Component of Vitrified Grinding WheelsThe type of bonding material used in making Vitrified Grinding Wheels is a critical factor in the product's design and performance. Eagle Superabrasives, Inc uses a superior bonding formula that ensures that its Vitrified Grinding Wheels exhibit exceptional grinding and precision performance. The bonding material offers excellent thermal management and stability, which results in more extended tool life and less downtime due to overheating. The company's advanced bonding technology combines resin, clay, and ceramic systems to create a hybrid bonding matrix that provides exceptional mechanical and thermal stability. The high level of hardness and wear resistance of the bonding matrix enhances the abrasive capacity of the grinding tool, resulting in a sharper final product. Additionally, the bond formation process ensures that the bond material has sufficient porosity, which helps to optimize the coolant flow during the grinding process. The bonding material also plays a significant role in the final surface finish that the grinding wheel creates. The company's Vitrified Grinding Wheels provide excellent accuracy and repeatability by delivering consistently superior surface finishes. The advanced bonding technology results in a wear-resistant surface that minimizes the grinding forces, which leads to a better surface finish. Superior Performance with Vitrified Grinding WheelsEagle Superabrasives, Inc's Vitrified Grinding Wheels provide superior performance on a vast range of materials. From carbide and tool steels to hard and brittle materials, the company's superabrasive tools produce excellent results. The tools' superior performance can also be attributed to their durability and accuracy, which make them suitable for both rough and precision grinding applications. The company's Vitrified Grinding Wheels are available in several customized designs and specifications to meet specific customer needs. The customization options include different abrasive grain sizes, diamond concentration, bond types, and more. The customizing options allow customers to choose the most suitable wheels for their specific applications, thus achieving optimum performance. ConclusionEagle Superabrasives, Inc's commitment to quality and superior performance is evident through its Vitrified Grinding Wheels. The superior bonding formula used by the company provides high performance, accuracy, and durability to meet different grinding needs. Additionally, the company's technical expertise offers customers an added advantage through expert advice during their product selection. With over four decades of experience, the company has established a reputation for innovation and excellence. In conclusion, if you're looking for the best quality superabrasive tools, look no further than Eagle Superabrasives, Inc.

Read More

Ultra-Thin 115mm Metal Cutting Blade Disc for Steel and Stainless Steel - Pack of 20

The Importance of Using High-Quality 115mm Metal Cutting DiscsWhen it comes to metal cutting, using a high-quality cutting disc is crucial for achieving clean and precise cuts. One such cutting disc that has gained popularity among professionals and DIY enthusiasts is the 115mm metal cutting disc.The 115mm metal cutting disc is a circular blade that is designed to cut through tough materials such as steel and stainless steel. It is available in various thicknesses, with 1mm being the most popular thickness for ultra-thin cuts. The disc has a diameter of 115mm, which is compatible with most 115mm angle grinders.One of the key advantages of using the 115mm metal cutting disc is its speed and efficiency in cutting through metal. With a maximum RPM of 13,300, it can quickly and easily cut through even the thickest of metals. Its ultra-thin design also means that it generates less heat during cutting, which helps to prevent warping, distortion, and discoloration of the metal.Another advantage of the 115mm metal cutting disc is its durability. Made from high-quality stainless steel metal, it is designed to withstand the rigors of heavy-duty cutting. It resists wear and tear, and can last up to 30% longer than standard cutting discs.When it comes to safety, the 115mm metal cutting disc is designed to reduce the risk of accidents. Its ultra-thin design means that there is less chance of kickback or snagging, while its reinforced construction enhances its stability and reduces the risk of breakages.Overall, the 115mm metal cutting disc is an essential tool for anyone who needs to cut through metal. Its speed, efficiency, durability, and safety features make it a must-have for professionals and DIY enthusiasts alike. Whether you are cutting through steel, stainless steel, or other tough metals, using a high-quality 115mm metal cutting disc is essential for achieving clean and precise cuts. To conclude, if you are looking for a reliable and efficient tool for metal cutting, 115mm metal cutting discs are the perfect choice for you. So, whether you are a professional or a DIY enthusiast, invest in high-quality cutting discs to achieve the best results.

Read More