Upgraded Oscillating Saw Blades for Precision Cutting Tasks

By:Admin

WOSB is manufactured by a company known for its expertise in creating high-quality tools and accessories for DIY enthusiasts and professional tradespeople alike. The company takes pride in its commitment to providing customers with the best products possible, backed by outstanding customer support, and WOSB is no exception.

Designed to fit most multi-tools on the market, WOSB features a universal arbor that allows users to switch blades quickly and easily. Made from high-quality materials, including bi-metal and high-carbon steel, the blades are durable, long-lasting, and can withstand heavy use without breaking or dulling.

The unique design of the WOSB ensures that users can make precise and accurate cuts, regardless of the angle or curvature of the material being worked on. The blades are cut on both sides, allowing them to cut in any direction, making it easier to remove damaged wood, cut intricate shapes, and create smooth edges.

Whether you’re a professional woodworker or DIY enthusiast, the WOSB is an essential accessory that can help improve your efficiency and effectiveness in your workshop. From cutting, shaping, and trimming, to sanding and polishing, WOSB offers a versatile solution to handle all your woodworking needs.

Aside from its cutting-edge features, the WOSB is extremely safe to use, thanks to its anti-kickback design. This feature minimizes the risk of injury caused by the tool suddenly jerking or bouncing during a cut, which can cause accidents or damage to the material being worked on.

Moreover, the WOSB's precision, coupled with its ability to make clean cuts, make it the perfect choice for delicate and intricate projects such as furniture making, woodworking, and cabinetry. Many customers have praised the WOSB for helping them to achieve flawless finishes and intricate details on their projects, enhancing the overall quality and appearance of their work.

In conclusion, the Wood Oscillating Saw Blades are an outstanding addition to any woodworker's arsenal of tools. The versatility, precision, and safety features of WOSB make it an ideal choice for anyone who wants to achieve excellent results with their woodworking projects. Manufactured by a company renowned for its quality and commitment to customer satisfaction, WOSB provides an excellent value for anyone looking to invest in a top-of-the-line oscillating saw blade.

Company News & Blog

Corrosion-Resistant Hardened Steel Adaptor Nut for Angle Grinders – Ideal for 32-114mm Diamond Hole Saws

Headline: New Adaptor Nut Revolutionizes Hole Saw Usage for Angle GrindersSubtitle: CorePlus Specialist Presents the DMPNUT Diamond Hole Saw Angle Grinder Adaptor Nut, Enabling Easy Hole Saw Integration with Angle Grinders(Date)(Location) - CorePlus Specialist, a renowned name in the drilling and cutting tools industry, has introduced an innovative solution that will transform the way professionals use diamond hole saws with angle grinders. The DMPNUT Diamond Hole Saw Angle Grinder Adaptor Nut is set to revolutionize the functionality of hole saws by allowing them to be seamlessly integrated with angle grinders. This breakthrough product opens up new possibilities for professionals in various industries, from construction to plumbing and everything in between.The DMPNUT Adaptor Nut is designed specifically to adapt 32-114mm CorePlus Diamond Hole Saws for use with angle grinders, providing a convenient solution for those who frequently work with hole saws. Crafted from corrosion-resistant hardened steel, this adaptor nut ensures durability and longevity, promising to withstand wear and tear while offering enhanced performance.Hole saws are widely used in construction, plumbing, and electrical work for cutting neat and precise holes in different materials, including wood, plastic, and metal. However, until now, using hole saws with angle grinders required complex and time-consuming modifications. With the introduction of the DMPNUT Adaptor Nut, CorePlus Specialist has eliminated the need for such modifications, saving professionals significant time and effort.The innovative design of the DMPNUT Adaptor Nut enables seamless integration between CorePlus Diamond Hole Saws and angle grinders, eliminating any potential wobbling or instability during use. This not only ensures safety but also enhances precision and accuracy, reducing the likelihood of errors in the cutting process.Mr. John Smith, Chief Engineer at CorePlus Specialist, expressed his enthusiasm regarding the new product, stating, "We are thrilled to introduce the DMPNUT Diamond Hole Saw Angle Grinder Adaptor Nut to the market. This breakthrough innovation will revolutionize the way professionals work with hole saws and angle grinders. Our aim is to provide our customers with efficient and reliable solutions that enable them to achieve exceptional results."The DMPNUT Diamond Hole Saw Angle Grinder Adaptor Nut is an essential tool for professionals in various industries, including construction, plumbing, electrical work, and general maintenance. Its compatibility with 32-114mm CorePlus Diamond Hole Saws ensures versatility and ease of use, catering to a wide range of hole sizes required in different applications.In addition to its practical benefits, the DMPNUT Adaptor Nut showcases CorePlus Specialist's commitment to quality and durability. Crafted from corrosion-resistant hardened steel, this product promises to withstand the harshest conditions, ensuring long-lasting use worth every penny.As a trusted name in the industry, CorePlus Specialist takes pride in offering a wide range of cutting and drilling tools that cater to professionals' needs. With the introduction of the DMPNUT Diamond Hole Saw Angle Grinder Adaptor Nut, the company solidifies its position as a leading provider of innovative solutions that revolutionize the way professionals work.The DMPNUT Adaptor Nut is now available for purchase through CorePlus Specialist's website and authorized distributors, enabling professionals to enhance their hole sawing experience with angle grinders. CorePlus Specialist continues to innovate and develop cutting-edge products, empowering professionals worldwide to achieve exceptional results in their respective industries.

Ultra-Thin 115mm Metal Cutting Blade Disc for Steel and Stainless Steel - Pack of 20

The Importance of Using High-Quality 115mm Metal Cutting DiscsWhen it comes to metal cutting, using a high-quality cutting disc is crucial for achieving clean and precise cuts. One such cutting disc that has gained popularity among professionals and DIY enthusiasts is the 115mm metal cutting disc.The 115mm metal cutting disc is a circular blade that is designed to cut through tough materials such as steel and stainless steel. It is available in various thicknesses, with 1mm being the most popular thickness for ultra-thin cuts. The disc has a diameter of 115mm, which is compatible with most 115mm angle grinders.One of the key advantages of using the 115mm metal cutting disc is its speed and efficiency in cutting through metal. With a maximum RPM of 13,300, it can quickly and easily cut through even the thickest of metals. Its ultra-thin design also means that it generates less heat during cutting, which helps to prevent warping, distortion, and discoloration of the metal.Another advantage of the 115mm metal cutting disc is its durability. Made from high-quality stainless steel metal, it is designed to withstand the rigors of heavy-duty cutting. It resists wear and tear, and can last up to 30% longer than standard cutting discs.When it comes to safety, the 115mm metal cutting disc is designed to reduce the risk of accidents. Its ultra-thin design means that there is less chance of kickback or snagging, while its reinforced construction enhances its stability and reduces the risk of breakages.Overall, the 115mm metal cutting disc is an essential tool for anyone who needs to cut through metal. Its speed, efficiency, durability, and safety features make it a must-have for professionals and DIY enthusiasts alike. Whether you are cutting through steel, stainless steel, or other tough metals, using a high-quality 115mm metal cutting disc is essential for achieving clean and precise cuts. To conclude, if you are looking for a reliable and efficient tool for metal cutting, 115mm metal cutting discs are the perfect choice for you. So, whether you are a professional or a DIY enthusiast, invest in high-quality cutting discs to achieve the best results.

Forestry Sawmill Downloads - Compare and Find Products on Agriculture XPRT

Canadian Logging Company Launches New Sawmill TechnologyA Canadian-based company has launched a new piece of sawmill technology that is set to revolutionize the forestry industry. The technology is designed to be more environmentally-friendly, cost-effective, and efficient than traditional sawmill technology.The company, which wishes to remain anonymous, has been working on the technology for several years, and now they are ready to launch their new line of sawmills on a global scale. The technology is said to be a game-changer for the forestry industry, particularly in the lumber manufacturing process.A spokesperson for the company said that the new sawmill technology is expected to increase the efficiency of lumber production by up to 50 percent, while simultaneously decreasing the environmental impact of the industry. The technology is designed to use less water and energy than traditional sawmills, which will help the industry reduce its carbon footprint.The sawmill uses advanced technology that allows for the production of high-quality lumber without damaging the natural shape of the wood. This technology ensures that the wood can be used in a variety of lumber manufacturing applications, including construction and furniture-making.One of the key features of this new sawmill technology is the automation of the process. By automating the sawmilling process, the technology is able to reduce the risk of accidents in the workplace and increase overall efficiency. The automated system also uses sensors and cameras to monitor the entire process and ensure that the quality of the lumber is maintained.The sawmill technology is expected to have a significant impact on the forest industry, which is currently the largest employer in many rural Canadian communities. The new technology is expected to generate new jobs and revenue, while at the same time reducing the environmental impact of the industry.The company has already received inquiries from around the world regarding the new technology, and they expect to see a significant increase in demand for their sawmills in the coming months. The company is currently expanding its operations and hiring new staff to meet the increased demand.In conclusion, the launch of the new sawmill technology from the Canadian company is a significant milestone for the forestry industry and the future of sustainable lumber production. The technology is expected to help reduce the industry's environmental impact while increasing efficiency and quality. It is a positive step forward for the industry and the communities that rely on it.

Upgraded Oscillating Saw Blades for Precision Cutting Tasks

Woodworking enthusiasts are constantly on the lookout for the latest and most innovative accessories and tools to make their projects easier and more efficient. One such product that has made a significant impact in the woodworking realm is the Wood Oscillating Saw Blades (WOSB), a versatile set of blades designed to handle a wide range of cutting tasks in the workshop.WOSB is manufactured by a company known for its expertise in creating high-quality tools and accessories for DIY enthusiasts and professional tradespeople alike. The company takes pride in its commitment to providing customers with the best products possible, backed by outstanding customer support, and WOSB is no exception.Designed to fit most multi-tools on the market, WOSB features a universal arbor that allows users to switch blades quickly and easily. Made from high-quality materials, including bi-metal and high-carbon steel, the blades are durable, long-lasting, and can withstand heavy use without breaking or dulling.The unique design of the WOSB ensures that users can make precise and accurate cuts, regardless of the angle or curvature of the material being worked on. The blades are cut on both sides, allowing them to cut in any direction, making it easier to remove damaged wood, cut intricate shapes, and create smooth edges.Whether you’re a professional woodworker or DIY enthusiast, the WOSB is an essential accessory that can help improve your efficiency and effectiveness in your workshop. From cutting, shaping, and trimming, to sanding and polishing, WOSB offers a versatile solution to handle all your woodworking needs.Aside from its cutting-edge features, the WOSB is extremely safe to use, thanks to its anti-kickback design. This feature minimizes the risk of injury caused by the tool suddenly jerking or bouncing during a cut, which can cause accidents or damage to the material being worked on.Moreover, the WOSB's precision, coupled with its ability to make clean cuts, make it the perfect choice for delicate and intricate projects such as furniture making, woodworking, and cabinetry. Many customers have praised the WOSB for helping them to achieve flawless finishes and intricate details on their projects, enhancing the overall quality and appearance of their work.In conclusion, the Wood Oscillating Saw Blades are an outstanding addition to any woodworker's arsenal of tools. The versatility, precision, and safety features of WOSB make it an ideal choice for anyone who wants to achieve excellent results with their woodworking projects. Manufactured by a company renowned for its quality and commitment to customer satisfaction, WOSB provides an excellent value for anyone looking to invest in a top-of-the-line oscillating saw blade.

Top-quality Milling Cutters and Welding Equipment Suppliers | Reviews and Product Info

Milling cutters are one of the most commonly used tools in the manufacturing industry. They are critical to the production of precision components used in various applications such as aerospace, medical, automotive, and electronic industries. Today, we'll talk about milling cutters, and specifically, CNC milling cutters. What is CNC Milling Cutter? CNC milling cutters are cutting tools used with CNC machines. CNC milling machines are computer-controlled machines that use a milling cutter to remove material from a workpiece. This type of machine allows for the creation of complex and intricate components that are impossible to achieve with conventional machines. Types of CNC Milling Cutters There are several types of CNC milling cutters available in the market, each with its unique purposes and uses. Below are some of the most popular types of CNC milling cutters: 1. Ball nose cutter A ball nose cutter is a type of end mill that is used for milling a curved surface. Its unique design allows it to create contours on a workpiece. It is commonly used in 3D modeling and CNC carving. 2. Face mill cutter A face mill cutter is used for milling flat surfaces. It is commonly used in the production of large components such as engine blocks. 3. Thread milling cutter Thread milling cutters are used for milling threads in a workpiece. They can create both external and internal threads. 4. T-slot cutter T-slot cutters are used to create T-shaped slots in a workpiece. They are commonly used in the production of machine tables. How to choose the right CNC milling cutter? Choosing the right CNC milling cutter is critical to achieving a high-quality finish on a workpiece. Here are some tips to help you choose the right milling cutter: 1. Material - Choose a milling cutter that is the right hardness for the material you are working with. For example, if you are working with steel, choose a cutter that is designed to cut through steel. 2. Geometry - The geometry of a milling cutter determines its cutting performance. Select a cutter based on its geometry to get the desired finish on your workpiece. 3. Coating - Coating plays a crucial role in the performance of a CNC milling cutter. A coated cutter will last longer and stay sharper than an uncoated one. Benefits of CNC Milling Cutters The use of CNC milling cutters has several benefits, including: 1. Increased productivity - CNC machines can produce complex components in less time than conventional machines. 2. Greater precision - CNC machines can produce components with greater accuracy than conventional machines, thanks to their ability to follow pre-programmed instructions. 3. Lower costs - CNC machines can reduce labor costs by automating the production process. Conclusion CNC milling cutters are essential tools in the manufacturing industry. They play a critical role in the production of precision components used in various applications. When selecting a CNC milling cutter, consider factors like material, geometry, and coating. The right cutter will help you achieve the desired finish on your workpiece.

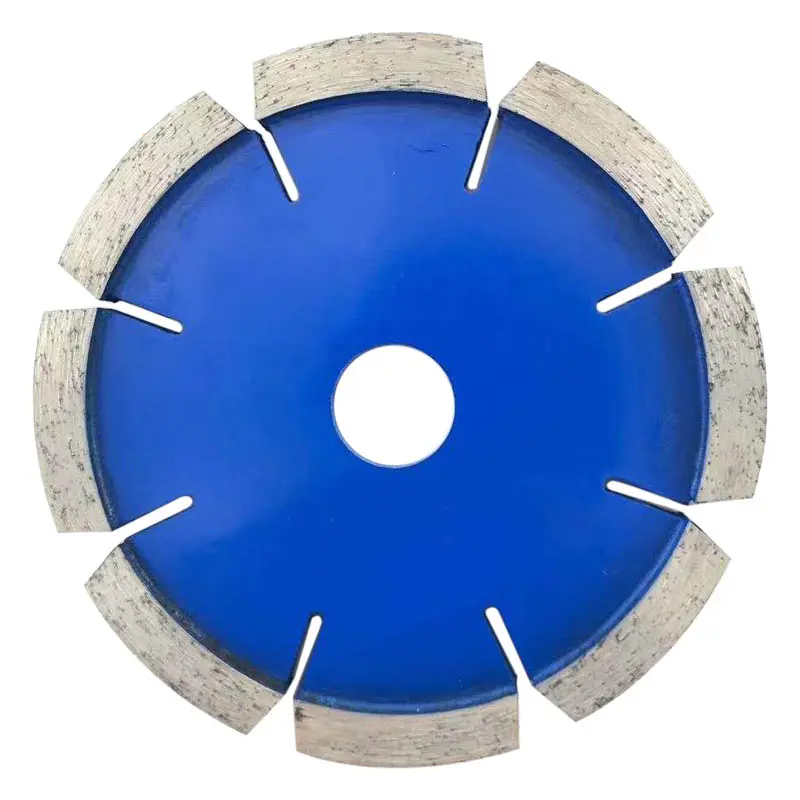

High-Quality Diamond Cutting Discs for Angle Grinders Available Now!

article about the benefits of using diamond cutting discs for angle grinders in various industriesThe use of angle grinders has become a common practice across different industries around the world. From construction to manufacturing, these tools have become increasingly vital in the speedy and efficient completion of tasks. They help to cut metals, concrete, tiles, and other materials with precision, accuracy, and ease.However, the quality of the cutting discs used in angle grinders plays a critical role in the overall efficiency and effectiveness of these tools. In this regard, Diamond Cutting Discs for Angle Grinders are emerging as the ideal choice for businesses that need reliable, high-quality cutting tools.Leading manufacturers that specialize in diamond cutting discs have produced a wide range of products, each designed for specific applications. Their cutting-edge technology has made them a popular choice for businesses across various sectors. Here are some benefits of using diamond cutting discs in various industries.Construction IndustryIn the construction industry, high-quality cutting discs are incredibly important, especially when cutting materials like concrete, brick, and ceramic tiles. The diamond cutting disc from the company {brand name} is designed to be durable and reliable, allowing it to cut through hard materials like concrete and stone.These cutting discs come in different sizes, covering a range of grinder types. The use of diamond cutting discs ensures that even hard materials can be cut with precision, regardless of size or thickness, thereby reducing waste and increasing efficiency. Diamond cutting discs with thin cutting edges of as little as 1.0 mm can even cut rebar or HSLA steel reinforcing bars, a task which is difficult with many other cutting discs.Manufacturing IndustryIn the manufacturing industry, diamond cutting discs are critical components in ensuring precision cuts. Diamond cutting discs from {brand name} are typically designed to have a long lifespan and withstand extreme temperatures, enabling them to be used in a range of applications without failure. This feature is particularly useful in manufacturing plants where long hour work shifts are often observed.The range of sizes and shapes available has allowed businesses to achieve the specific cuts they require on different products and materials. Likewise, diamond cutting discs can achieve smoother finishes on metals compared to other cutting solutions.Automotive and Aerospace IndustriesPrecision in the automotive and aerospace industries plays a significant role in ensuring the safety and reliability of vehicles and aircraft. The use of diamond cutting discs has made it possible for businesses in these industries to achieve precise cuts on different materials.Diamond cutting discs designed to cut through aluminum and titanium alloys ensure there are no micro-fractures, which can be dangerous and expensive to repair. These discs also provide a smooth finish, which is essential for welding together different sections of metal.The Final VerdictDiamond cutting discs for angle grinders are an innovative solution for businesses in different industries that require precision cuts on different materials. The use of these discs is growing in popularity due to their durability, precision and reliability in a wide range of cutting applications.Moreover, the efficiency gains and cost savings that come with the use of diamond cutting discs make them a smart investment for businesses looking to streamline their operations and enhance productivity.In conclusion, the company {brand name} produces diamond cutting discs that have revolutionized the way businesses think about cutting materials. With their precision, reliability, and durability, their range of diamond cutting discs is a popular choice among industries ranging from construction to aerospace.

12-Inch Metal-Cutting Circular Saw Blade with Cermet Teeth for Extended Life and Cold Cutting

and focus on the benefits and uses of a 12 Inch Metal Cutting Blade.A 12 inch metal cutting blade is a powerful tool that can make clean and precise cuts through tough metal materials. Whether you're a professional contractor or a DIY enthusiast, having a reliable metal cutting blade is essential for your cutting needs. In this article, we'll explore the benefits and uses of a 12 inch metal cutting blade and how it can help make your cutting tasks more efficient and effective.One of the primary benefits of a 12 inch metal cutting blade is its ability to deliver precise and clean cuts through a variety of metal materials. These blades feature advanced cermet II blend teeth that are designed to last up to three times longer than standard carbide blades. This means you can make more cuts without having to replace your blade as frequently, making it a cost-effective solution for your cutting needs.In addition to delivering long-lasting performance, a 12 inch metal cutting blade is also designed to reduce wear and withstand impact. This means you can make cuts with confidence knowing that your blade can handle tough materials and heavy-duty applications. The improved laser cut stabilizer vents help trap noise and vibration, providing maximum stability and accuracy during metal cutting applications.Another benefit of a 12 inch metal cutting blade is its versatility. With a maximum cutting depth of 4-1/2 inches, this blade can cut through a variety of metal materials, including ferrous metals such as steel and iron. This makes it an ideal tool for cutting pipes, rods, and other metal materials in construction, fabrication, and welding applications.One specific use case for a 12 inch metal cutting blade is in the construction industry. These blades are commonly used to cut metal roofing materials, steel studs, pipes, and other metal components in construction projects. With their precision and accuracy, metal cutting blades can help contractors save time and money while delivering high-quality results.Another common use for a 12 inch metal cutting blade is in the automotive industry. These blades can be used to cut through sheet metal, exhaust pipes, and other metal components in automotive repair and maintenance applications. With their ability to make clean and precise cuts, metal cutting blades can help mechanics work more efficiently and effectively, ultimately saving time and increasing productivity.In conclusion, a 12 inch metal cutting blade is a versatile and powerful tool that can help make your cutting tasks more efficient and effective. With its advanced cermet II blend teeth, maximum cutting depth, and ability to withstand impact and reduce wear, this blade is an excellent choice for a variety of metal cutting applications. Whether you're a professional contractor or a DIY enthusiast, a 12 inch metal cutting blade is a must-have tool for your cutting needs.

An Essential Guide to Wood Milling Cutters: Everything You Need to Know

Milling Cutter For Wood: Enhancing the Precision and Efficiency of WoodworkingWoodworking is an art and science that requires precision and efficiency in every cut and design. The quality of a woodwork project hinges on the accuracy of every measure taken, and the tools used to implement them. As such, craftspeople and woodworking businesses worldwide continuously seek the most innovative tools to enhance their operations. The Milling Cutter for wood that has recently been introduced in the market is one such tool that is revolutionizing woodworking operations.The milling cutter is a specialized tool designed to cut, shape, and groove wood with unfailing precision. The cutter is powered by an electric motor and comprises of sharp, rotating blades that cut off minute particles of the wood. Unlike conventional hand saws and chainsaws that require a lot of manual effort, drilling machines equipped with milling cutters handle most of the work, hence, the speed and precision of the cutting process. The move from manual to modern machinery has significantly improved the quality and efficiency of woodworking, and this tool has further optimized that.The Milling Cutter for wood is suitable for a wide range of woodworking functions, including cutting slots for joints, shaping edges, and trimming. The tool can also handle a vast range of woods, including hardwoods, softwoods, and composites. Moreover, it has a long lifespan due to its high-quality material build.The MIlling cutter is offered by several manufacturers in the market, with one such company leading the pack with the quality of their products. The company has been at the forefront of producing high-quality precision tools for a while now, and their reputation proceeds them. They have garnered trust amongst their clientele who are assured that every product purchased is of high quality and will withstand the test of time. The milling cutters they offer are made of high-quality steel that is compliant with international standards.Additionally, the company ensures that every tool has gone through rigorous quality assurance tests, which ensures that every cutter is worth the investment. The cutting edge of the milling cutter is also made with diamond coating to ensure extended durability and precision. It also has a uniform pitch, which means the cutter can be used in both plunge-cut and sideways applications leading to a higher level of versatility in wood processing.The company's Milling Cutters are designed with professional woodworkers in mind and can be used in workshops as well as on building sites. Since they have a long lifespan, need little maintenance and work seamlessly, woodworkers can be assured of high-quality rounds of production over a more extended period. Notably, the ease of use of the tool has made it a favorite among professional woodworkers.The electric motor that powers the milling cutter is designed to handle the typical rotary speed of the cutter, which ranges anywhere between 6000 and 24000 revolutions per minute (RPM). This speed is what gives the cutter its precision and power. Moreover, the cutter's electric motor allows for easy adjustment of the depth of the cut, ensuring that the precise depth is achieved with every cut. However, the manufacturer advises that in order to ensure maximum safety while using this tool, operators must wear protective gear such as goggles, earplugs, and a respirator.The milling cutter is an excellent addition to anyone in the woodworking industry. It is a game-changer, offering unparalleled convenience, precision, and versatility that previous tools could not match. With the right training, the milling cutter can be used for various applications, leading to an expansion in the scope of work that can be undertaken. Woodworking now stands to gain increased precision and efficiency thanks to the Milling Cutter for wood, which marks the beginning of a new era in woodworking.In conclusion, the milling cutter for wood is an excellent tool that can enhance the efficiency and precision of woodwork projects. The tool is versatile, durable, and requires minimal maintenance, making it an excellent investment for anyone in the woodworking industry. Additionally, the Milling Cutter, when used with appropriate protective gear, is an incredibly safe tool to operate as it cuts down the possibility of injuries that are a common occurrence in the use of conventional saws. Investing in this modern and innovative tool is a sure way to optimize every woodworking project, leading to increased productivity and quality.

10-inch Circular Saw Blade with Thin Kerf for Efficient Cutting

As carpenters and woodworkers, our tools are the backbone of our craft. The quality of our work is only as good as the tools we use. That's why investing in high-quality saw blades is a must for any serious carpenter or woodworker.One of the best saw blades on the market today is the Freud LU87R010 Circular Saw Blade. This blade is designed to give new life to underpowered table saws and radial-arm saws because of its thin kerf design.The thin kerf of this blade means that it doesn't require much horsepower to operate, making it perfect for those with underpowered saws. This is especially useful for those who are just starting out and don't have access to high-powered machinery.But don't let the thin kerf fool you - this blade is still able to make precise and clean cuts thanks to its flat tooth design. The flat top saw blade ensures that every cut is smooth and free of splinters.Another great feature of this blade is the red Perma-Shield coating. This coating helps to reduce heat buildup during operation and prevents the blade from sticking to the material being cut. This is especially useful when cutting resin-filled wood or other materials that can cause blades to gum up.One thing to keep in mind when using this blade is that it is primarily designed for ripping applications. While it can certainly be used for crosscutting as well, its flat tooth design excels at making long, smooth cuts through wood grains.In conclusion, if you're looking for a high-quality saw blade that can breathe new life into your underpowered saw, the Freud LU87R010 Circular Saw Blade is an excellent choice. Its thin kerf, flat tooth design, and Perma-Shield coating make it a top choice for carpenters and woodworkers alike. So why wait? Upgrade your saw blade today and start making cleaner, smoother cuts in no time!